For efficient product development in micro- and nanotechnology

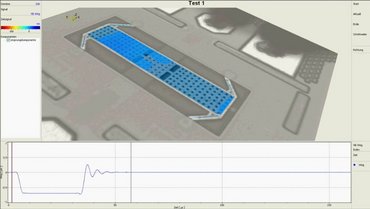

Precise, reliable and fast measuring technology for characterizing and monitoring the quality of devices is decisive to in developing and producing microsystems. This is all the more important since microsensors are increasingly taking over safety-related tasks too – placing high demands on reliability and functional safety. A robust design and high production precision play a key role in this regard. Active microelectromechanical structural elements such as MEMS actuators or sensors need suitable optical measurement methods, since purely electrical characterization isn’t enough.

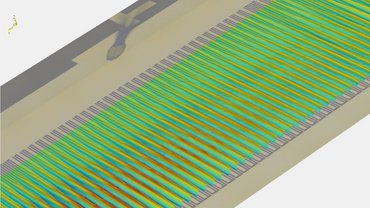

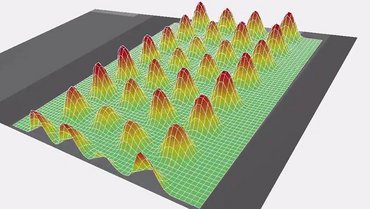

Polytec’s Micro System Analyzers are ideal for this. On the one hand, they enable determination of the surface topography with a high resolution and, on the other, they allow for precise characterization of the dynamic motion behaviour too. Dynamic measurement using laser Doppler vibrometry is characterized by a high frequency bandwidth and extremely good displacement amplitude resolution. This measuring technology even enables vibration measurements up to the high MHz range (and even the GHz range) – which is required for an ever-growing number of microtechnology applications.

Laser vibrometry focusing on the small details

Characterize small and delicate structures in a non-contact way. Analyze vibration, acoustics and dynamics. Measure biomedical samples, electronics components and microstructures like MEMS by light, without mass-loading, and from DC up to the GHz range on a large bandwidth. Laser vibrometers focus on the small details, measuring deflection shapes for model validation. They assess the frequency response and determine resonance frequency, impulse response and Q factor. No matter how big or small – Polytec vibrometers measure it!