Improved quality in hydrogen tanks, blowers, pumps & compressors

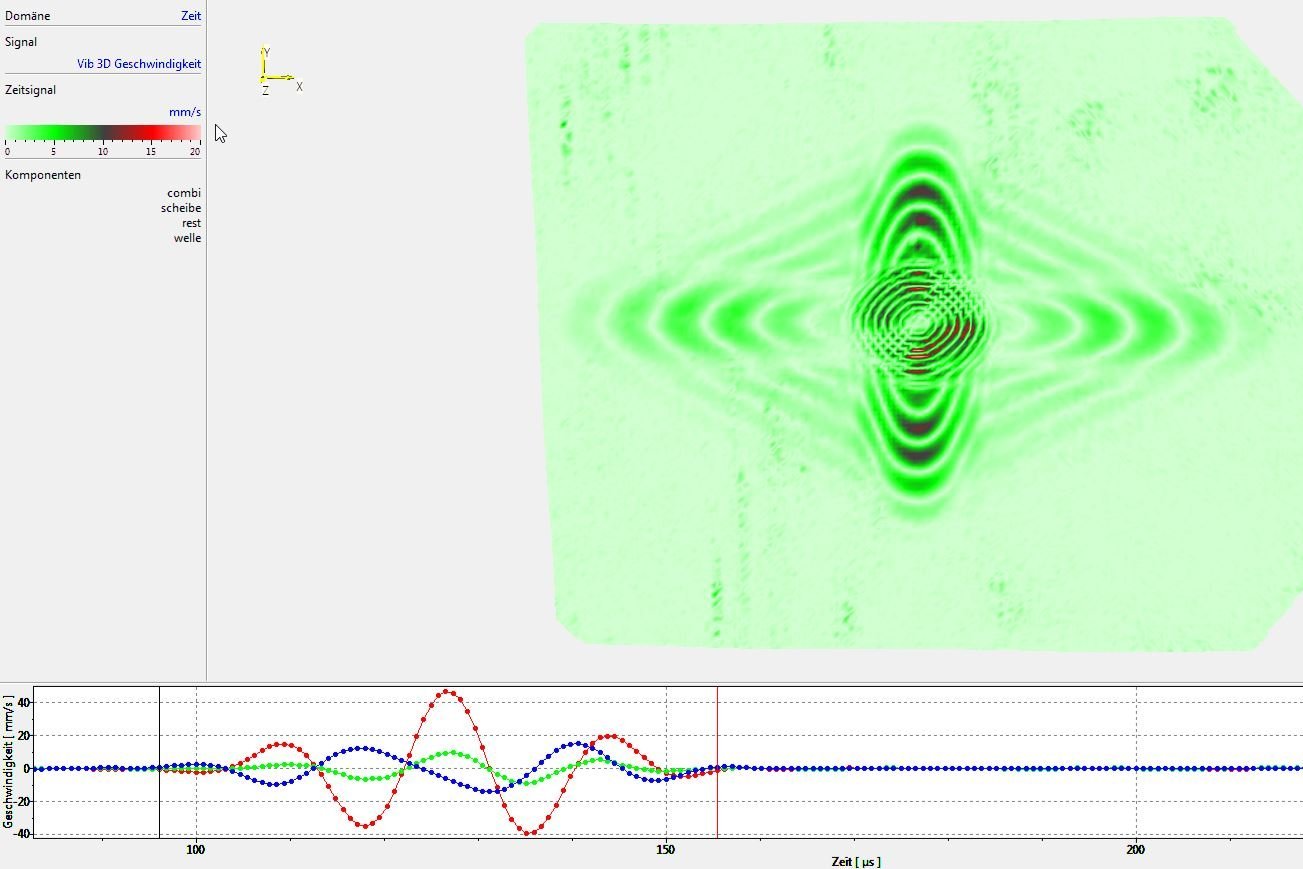

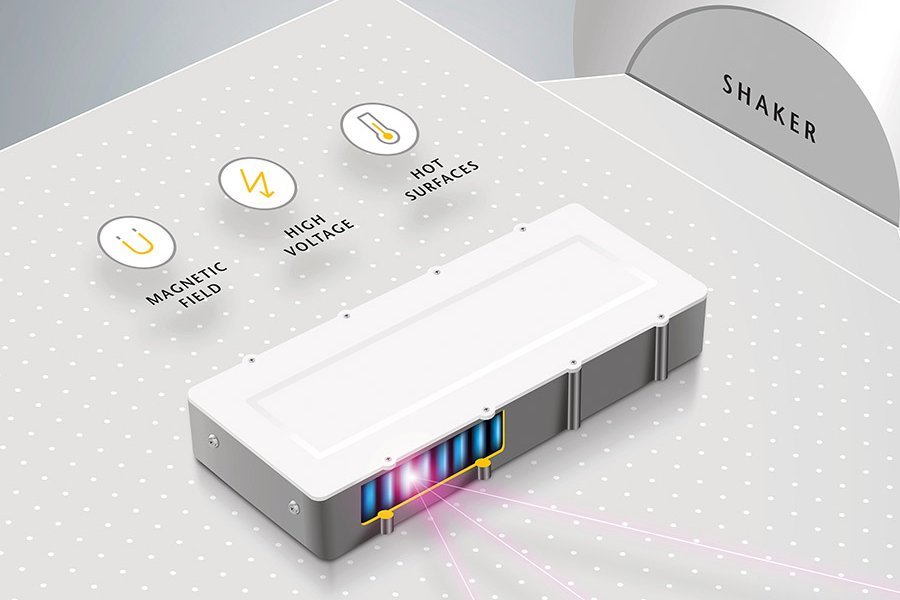

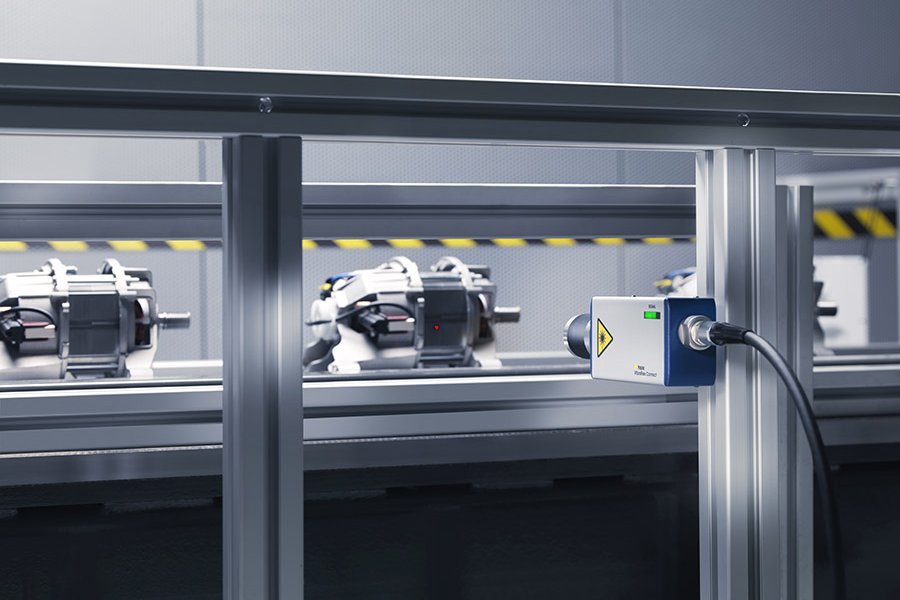

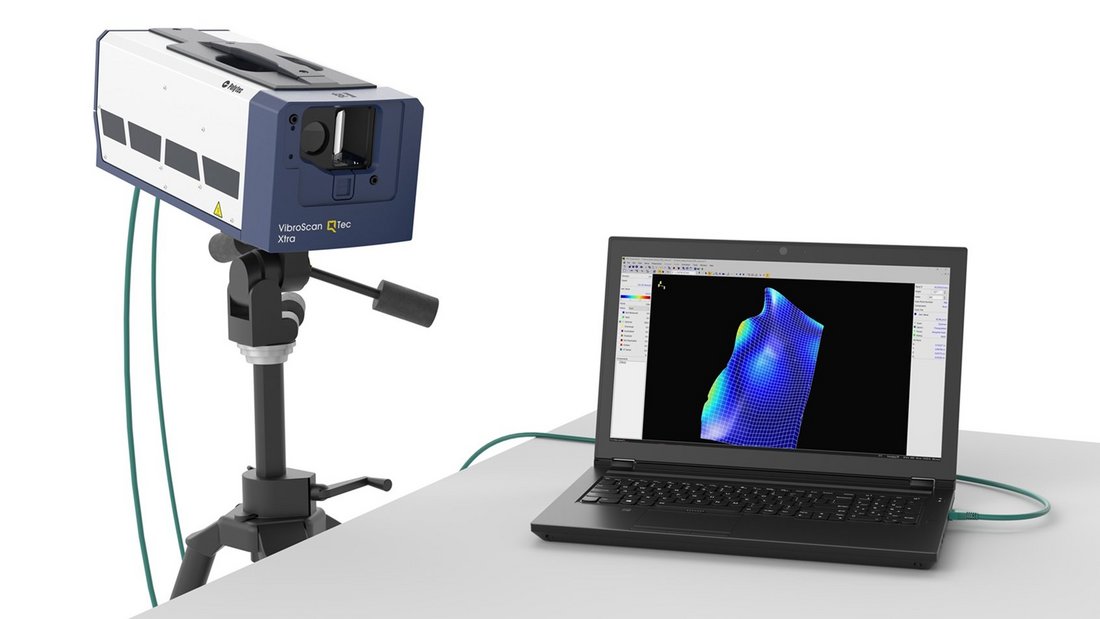

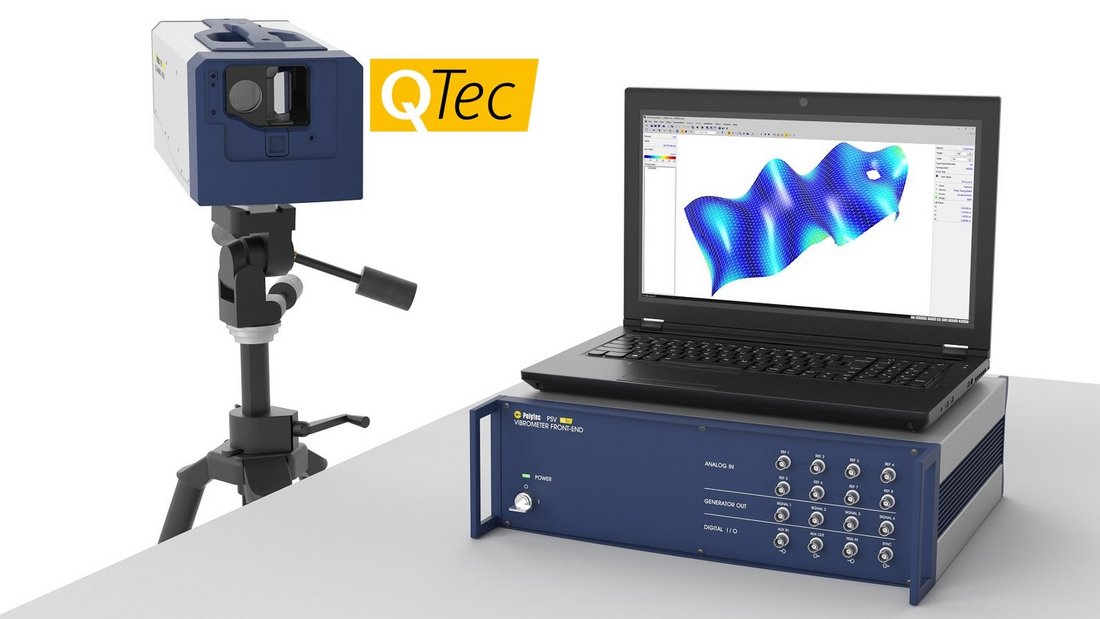

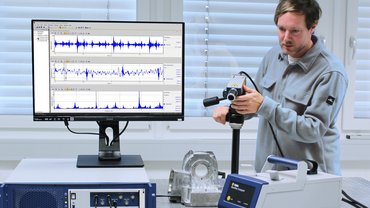

In fuel cell testing, material research of hydrogen tanks or of components such as injection valves, compressors (air system), blowers or pumps on the cooling side, Polytec Laser Doppler vibrometers assist in thourough vibration analysis. Polytec’s range of non-contact vibration measurement sensors help validate the FE model, visualize the operational deflection shape (ODS) of both the single component or assembly, can identify components with highest contribution to fuel cell vibration and thus noise or for NVH testing (noise, vibration and harshness).

Measure and validate your H2 components

Why laser vibrometers for H2 component testing

- Non-contact: Non-reactive, even in hard-to-reach areas

- Auto focus: Reliable measurement results at short and long distances

- Reliable: Unaffected by ambient noise

- High precision: Valid data detecting even small differences

Quiet & reliable fuel cells: NVH testing of hydrogen technology

To become fully accepted in vehicles the fuel cell technology has to be reliable, safe and comfortable. Directly related to comfort is the noise level of the vehicle which should be as low as possible. Thus, vehicle manufacturers need to ensure that each system component used in the vehicle is not dominating the overall noise level by tonal noise.

Test H2 components on a broad frequency bandwidth!