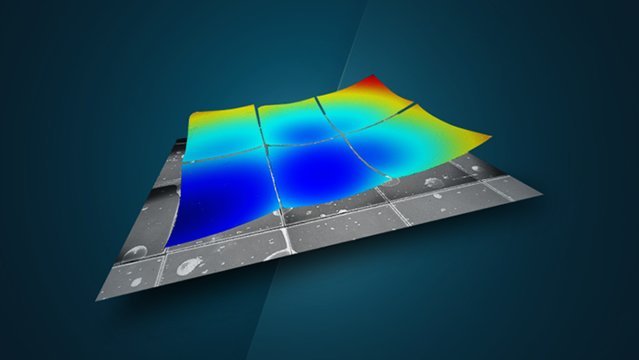

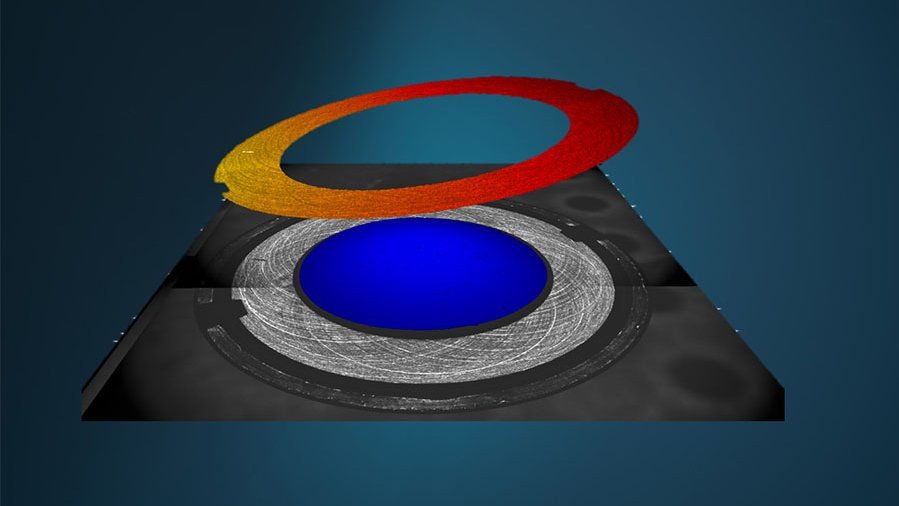

Combined measurement of surface roughness and form deviation

The TopMap Pro.Surf+ conveniently determines surface roughness and form deviation in a single measurement system – precise, reliable and cost-efficient. The additional roughness sensor and smart data acquisition takes the high-end surface measuring system TopMap Pro.Surf to the next level forming an all-in-one instrument. The resulting Pro.Surf+ is ideal for measuring precision surfaces – in the metrology laboratory, close to production and even right in the production line thanks to a high level of repeatability.

Highlights

- Quick and precise 3D surface characterization, plus roughness measurement

- All-in-one system captures all surface details

- Non-contact measurement principle and traceable measurement results

- Smart Scanning technology and filter wheel for almost all surfaces

- Large measurement volume of 230 x 220 x 70 mm³

- Telecentric lens measures even low-lying points

- Safe sample handling thanks to a long stand-off distance

- Automatic component recognition without any need for mechanical mounting

- Easy-to-use and automatable measurement and analysis software