Length measurement on roll-fed material and piece goods

Determining the velocity provides the basis for measuring the length. The length is calculated based on the velocity profile while the measured object passes through the measuring location. LSV Laser Surface Velocimeter automatically recognize whether the material is in the correct measuring position and can start/stop the length measurement accordingly. To achieve maximum measurement accuracy the LSV offers you the option of connecting light barriers as a means of starting or stopping the length measurement. This means you can link up several light barriers with one another to obtain a variety of application options. This may include, for example, controlling the length measurement using both trigger inputs, thereby increasing accuracy.

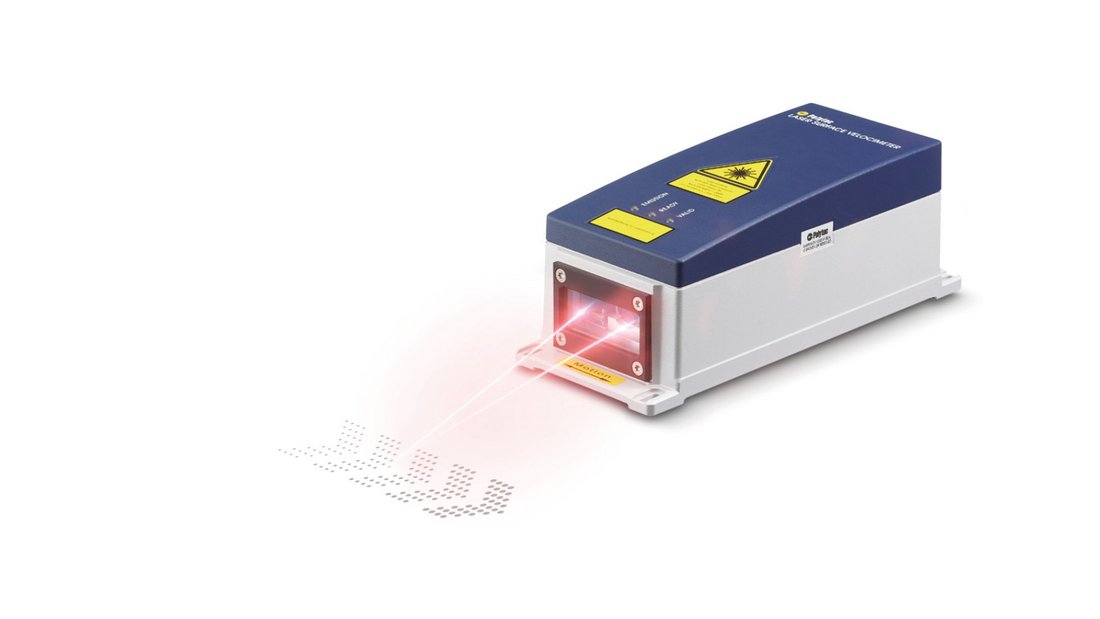

Laser surface velocimeters (LSVs) from Polytec are ideally suited because they can conduct measurements on almost any surface and they are not susceptible to contaminated surfaces. The non-contact measuring technique makes it possible to eliminate any negative influences on accuracy, such as slippage and wear, simultaneously. The product being subjected to the measurement also remains intact. Another benefit of Polytec systems is the flexible interface concept – it enables length readings via encoder output, serial interfaces, LAN, Profibus and Profinet.

Conveyor and drive belt length measurement

In a specific case, a world leading manufacturer of conveyor and drive belts uses several Polytec LSVs for carrying out length measurements at cutting stations. This means that customer-specific cuts can be automated, simplifying the process significantly. The cut-to-length accuracy using the LSV is independent of the belt surface and achieves a precision of 0.1%

Furthermore, Polytec industrial laser sensors are typically used for a variety of length measurement processes in the converting and textile industry:

- winding sheet materials

- cutting-to-length during fabrication

- position sensing in printing processes