Minimizing noise and wear

As the drivetrain is the initial source of noise, wear and even driving discomfort, understanding its dynamics is vital if a vehicle is to be a success. Polytec’s optical measuring technology lends your production facilities a helping hand with tasks where they need it most: from inspecting the stroke of the injection valve needle, over characterizing the valve elevation curves, to measuring torsional vibration at the downforce transmission paths. You can also establish the design of cardan and constant velocity drive shafts and characterize dual-mass flywheels for better driving comfort.

Polytec’s laser vibrometers have next to no frequency limitations, so, working together with you, they cover the entire scope of use for any acoustic and structural dynamic phenomena. This is precisely why they are so well-suited to analyzing high-frequency phenomena such as rattling and whining sounds in the gearbox. Scanning measurements, on the other hand, use detailed operational deflection shapes to illustrate solution processes, with a view to preventing acoustic radiation through the enclosure.

Polytec Magazine

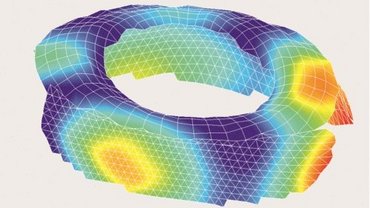

Experimental modal analysis of gear wheels

Measurements using broadband piezoelectric excitation