Reliability testing on electronic and mechatronic systems

When it comes to traffic safety and competitiveness, the reliability of electronic components is a key issue in the automotive and aviation industries. Scanning vibrometry has proven to be a key measurement method for mechanical tests in this regard, so users can characterize the dynamic behaviour of both printed circuit boards and mechatronic systems. Accelerometers cannot be usefully applied to small structures. Laser measurements, however, enable performance of precise modal analyses across a wide frequency range from just a few Hz to 50 kHz. When used in conjunction with FEM and continuous tests, laser measurements provide an efficient way of optimizing the printed circuit board design and layout with a view to avoiding undesirable vibration stresses that can shorten the service life.

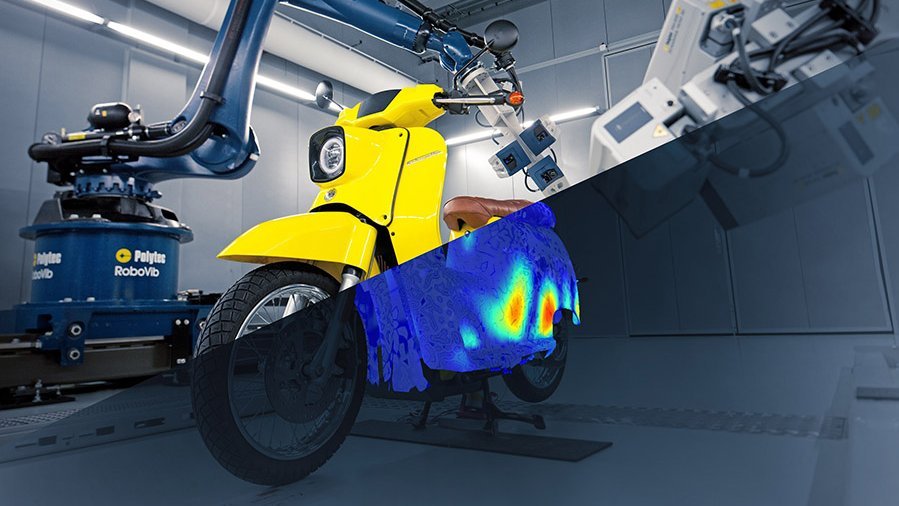

But that’s not all. Non-contact vibration measurement with laser vibrometers is helpful even for larger power electronic systems, such as converter modules for high-voltage direct current transmission which are used, for example, in offshore wind farms.. Their converter function can cause the converter structure to mechanically vibrate in an undesirable way, potentially overstressing it. Make specific design improvements by using 3D scanning vibrometry to determine the natural frequencies and deflection shapes, check whether improvements have been successful by repeating the vibration tests.