Surface metrology plays a crucial role in ensuring product quality and performance in precision engineering and other manufacturing.

Surface metrology involves the measurement and characterization of surface features, including roughness, texture, and other topographical aspects.

Why measure surfaces?

Measuring surfaces is important because surface characteristics play a critical role in manufacturing and product performance. Measuring surfaces allows manufacturers to ensure that the products they create meet precise design specifications and functional requirements. This process is not just about creating visually appealing surfaces; it involves understanding the surface's numerical data that can significantly impact the product's behaviour and performance in real-world applications.

Everyone is familiar with consumer products where the feel in your hand makes a difference to how you feel about them. Surface metrology influences consumer perceptions of quality and refinement. The tactile and visual appeal of surfaces, such as the smoothness of a mobile phone or the finish of a car's interior, directly affect buying decisions, making surface measurement a crucial aspect of both product development and marketing.

Beyond what you can physically perceive, nanoscopic surface measurements help manufacturers improve quality control by providing detailed insights into the surface characteristics that impact performance. For instance, in the automotive industry, the surface texture of engine components such as bearings have to be optimized to retain lubricants and minimize wear. Leads to parts that function better, leading to longer lasting and more reliable vehicles.

What is a “surface characteristic”?

A surface characteristic refers to the specific features and properties of a surface that determine its texture, appearance, and behaviour. These characteristics are crucial because they can significantly affect how a product functions and how it is perceived by users. Let's break down some of the key surface characteristics and why they matter:

Roughness is the small, finely spaced deviations on a surface. It's often what we think of as the "texture" of a surface. On a larger scale roughness can affect how a product feels to the touch and how it interacts with other surfaces. A rough surface might create more friction, which could be beneficial for gripping but detrimental if a smooth, low-friction surface is needed.

Smoothness is the opposite of roughness. It describes how even and flat a surface is. A smooth surface can reduce friction, improve movement, and enhance the aesthetic appeal of a product. For instance, the smooth glass screen of a smartphone not only looks sleek but also allows for easy touch navigation.

Flatness refers to the overall evenness of a surface. It's about how level the surface is when compared to a perfect plane. Flatness is crucial in applications where precise alignment and fitting are necessary, such as in mechanical parts of engines or in construction materials.

Texture encompasses the pattern and arrangement of the surface's features. This could include grooves, bumps, or other repeated designs. The texture of a surface can influence how it interacts with light (affecting its appearance), how it feels to the touch, and how it performs in practical applications, such as grip and wear resistance.

Waviness is a measure of the more widely spaced deviations on a surface, different from roughness which deals with finer details. It can affect how a surface will function under different conditions, such as how it will wear over time or how it might cause vibrations when in motion.

Polytec Topography Instruments

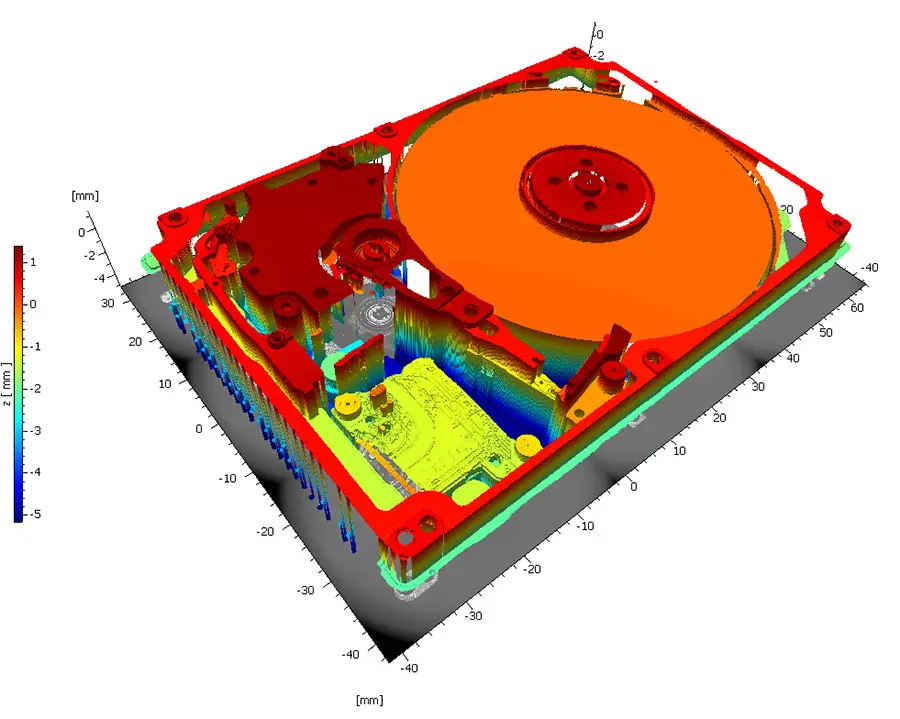

The Polytec range of topography instruments includes advanced optical systems designed for non-contact surface measurements. These instruments use cutting-edge technology to measure surfaces accurately without touching them, which is particularly useful for delicate materials.

Key advantages:

- Non-Destructive Testing: They don't damage the surface being measured, making them perfect for sensitive materials.

- High Precision: They can measure very small details with great accuracy.

- Versatility: They work on a wide range of materials, even those that are difficult to measure with traditional methods.

Example industries and applications:

Automotive Industry: Ensuring that engine parts last a long time and work efficiently is vital. For example,Ensuring the flatness and smoothness of fuel injector surfaces prevents leaks and ensures efficient fuel delivery.

High-end optical components: Optical components like lenses and mirrors in high precision environments need to be extremely smooth to work correctly. Any tiny imperfection can lead to major issues. Polytec surface profilers are used to measure these surfaces, ensuring they meet the high standards necessary for applications like telescopes and other high-precision instruments.

Medical Implants:The surfaces of implants such as hip joints and dental fixtures are crucial for their success and longevity. The surface characteristics determine how well these implants integrate with the human body. Polytec instruments provide the precision needed to measure and optimize these surfaces, ensuring they are suitable for long-term use.

Aerospace and Defence: The quality and performance of components in aerospace and defence are paramount. For example, the surfaces of optical systems used in satellites and guided missile systems must be meticulously measured and characterized. Polytec topography instruments are employed to ensure these surfaces meet the high standards required for such critical applications.

Polytec topography instruments are indispensable tools in modern manufacturing and engineering. By providing high-precision, non-contact surface measurements, they help industries achieve higher quality standards, enhance product performance, and innovate with confidence. Whether in automotive, medical, optical, or aerospace applications, Polytec leads the way in surface metrology, delivering solutions that meet the ever-evolving demands of technology and industry.

By leveraging advanced technologies and understanding the critical importance of surface characteristics. Polytec surface profilers empower engineers and manufacturers to optimise their products for quality, reliability, and performance.

Find out more about our surface profilers here or contact us to find out if our instruments are right for your application.