Tension control on sheet materials

Processing sheet materials means keeping the sheet tensioned. If the tension is too little, then the product "sags" and may become entangled. If it is too much, then the product can become overstretched and end up becoming damaged or ripped as a result. In order to accurately determine this tension between two different points in the process, it is essential to measure the velocity at both points. You can then calculate the tension from the difference).

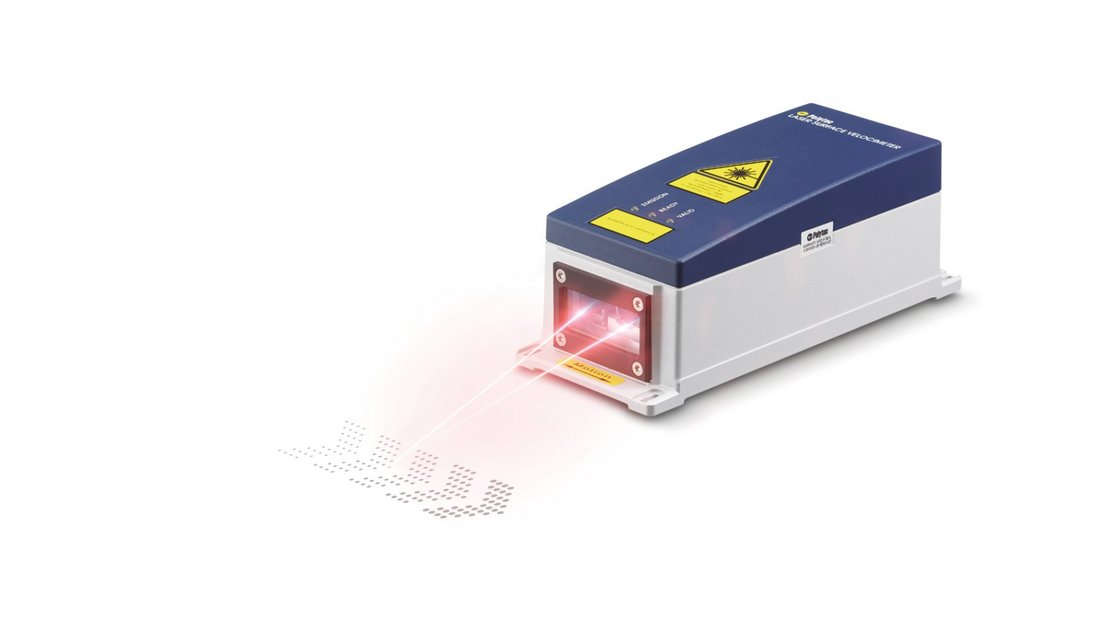

Laser surface velocimeters (LSVs) from Polytec are ideally suited because they can conduct measurements on almost any surface and they are not susceptible to contaminated surfaces. The non-contact measuring technique makes it possible to eliminate any negative influences on accuracy, such as slippage and wear, simultaneously. The product being subjected to the measurement remains intact too. The increased precision in measurement enables you to monitor the tension more closely, thereby optimizing the process while preventing damage to the product from tension fluctuations. The result: You increase quality while at the same time reducing waste.

Practical examples

Polytec LSVs are used in various applications in the paper, cardboard, & packaging industry as a means of regulating tension:

- in joining sheet materials, i.e while changing rolls of paper

- when processing sensitive material such as thin paper

Non-contact LSV velocity sensors in paper production

A Polytec LSV was installed in a paper factory because of frequent downtime when changing rolls of paper in its coating machine. Integrating the LSV into the process control allowed rolling velocities to be aligned exactly with one another with an accuracy of 0.1 %. This resulted in a significant reduction of tension fluctuations when joining the paper webs and has already led to savings equivalent to the investment costs in under a year