Optimize lightweight construction with laser precision

Lightweight construction forms the basis for better construction. The body shell offers the best potential in this regard. High tensile steels, aluminum and composite materials made from carbon fiber-reinforced plastic are being used instead of conventiopmal car body steel. Joining methods such as bonding and riveting are entering production processes, making simulation calculations susceptible to faults since joint attenuation cannot be determined with any real degree of certainty. Consequently, proof from an experimental modal analysis is more important than ever before during FE model validation.

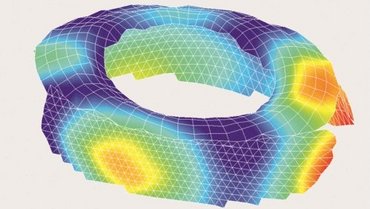

Since fewer prototypes are used nowadays, each optimization step needs to be faster and more reliable. Even lightweight bodies tend to drone, which is precisely why high-frequency mode validation is a topic for the future too as regards the acoustic calculation. A well-validated inventory model is normally used as a basis for the next generation. The better the model, the earlier a new vehicle’s properties can be calculated.

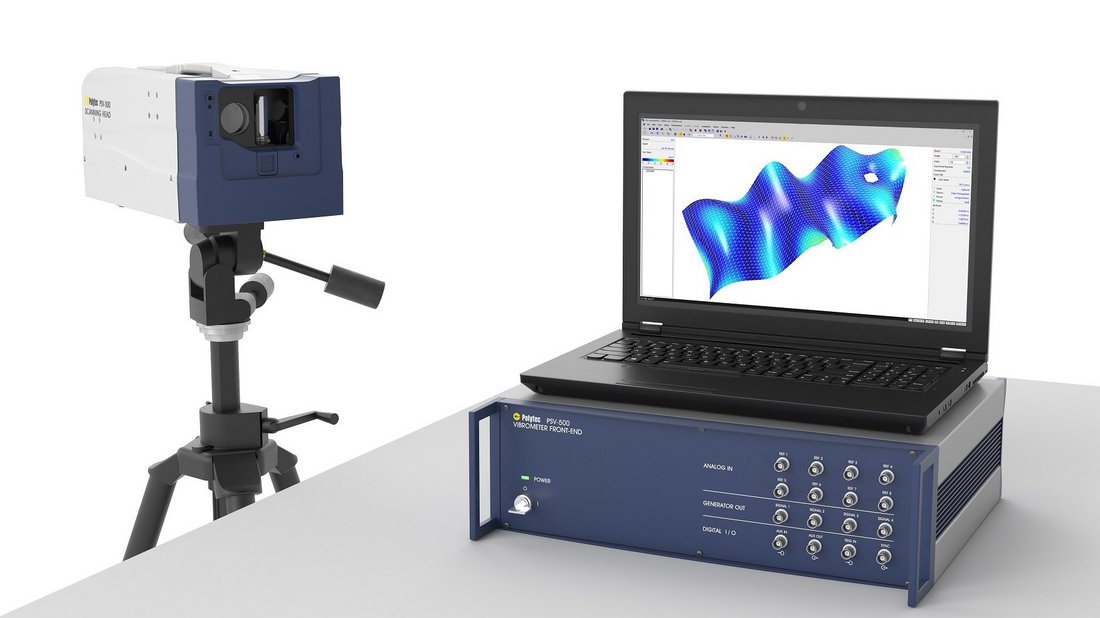

Lightweight bodies long for lightweight measuring technology, the non-contacting method per laser light is the ideal sensor technology. In offering you the 3D Scanning Vibrometers and the automated RoboVib® solution, Polytec is providing you with a highly productive tool that is extremely beneficial to you:

- Avoid impact on the sample thanks to zero mass loading

- Directly transfer the geometries data from FE models

- Automated measurement even overnight saves time

- High spatial resolution allows validating acoustic simulations