Manufacturing medical devices with maximum precision

People’s health is always the top priority in medicine. Therefore it is particularly important to ensure a consistent level of quality and reliability in medical device production. High-precision measurement and rapid analysis are very much in demand here, since even minor deviations can sometimes lead to unforeseeable and serious consequences.

Production testing on membranes for nebulizers and medical instruments

Pari GmbH manufactures nebulizers to treat respiratory diseases that accurately meter the liquid drug. The liquid is pressed through the holes in a membrane, which is stimulated to produce ultrasonic vibrations by piezo elements, and atomized. Using laser vibrometry guarantees a consistent nebulizer quality and thus an excellent reproducible drug effect for the patient.

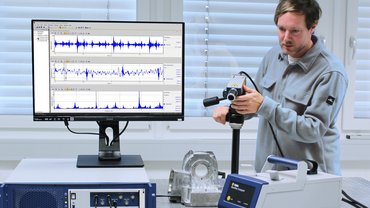

Polytec’s laser vibrometers also allow the detailed examination of the membrane’s vibration behaviour at product development stage and thereby enable continuous optimization of design and performance.

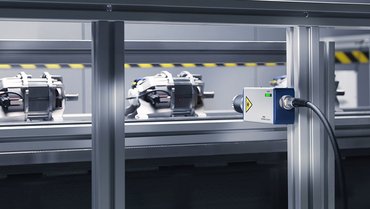

Complete quality control in production also uses the contactless measurement method to ensure zero-fault quality. A semi-automatic measuring station was developed together with Polytec for this very purpose. Compact laser vibrometers from Polyec measures the membrane’s movement with zero contact. Using production testing software from Polytec saves and analyses measured vibrometer data during the manufacturing processs allowing reliable pass-fail decisions as in-line or end-of line tests. Such complete production testing solutions from Polytec enable quality engineers around the globe in their every day quality assurance to continuously improve their yield and to reduce pseudo rejects.