Fast and efficient determination of stress and strain distribution

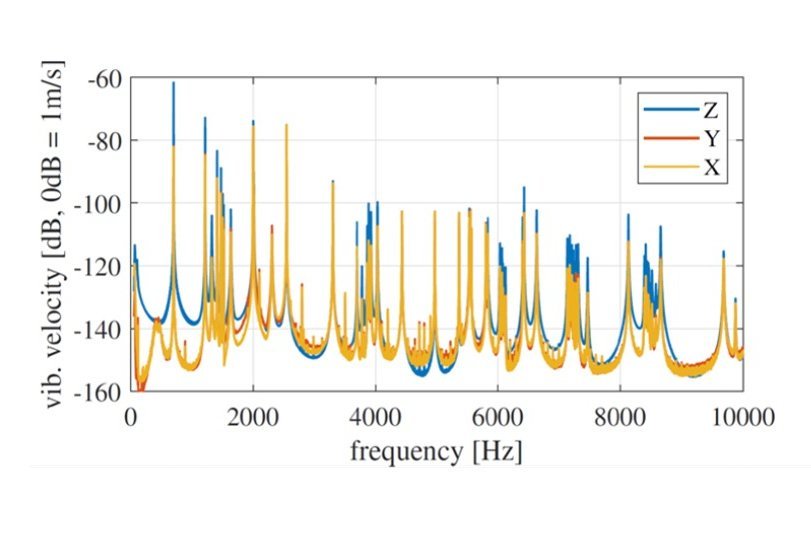

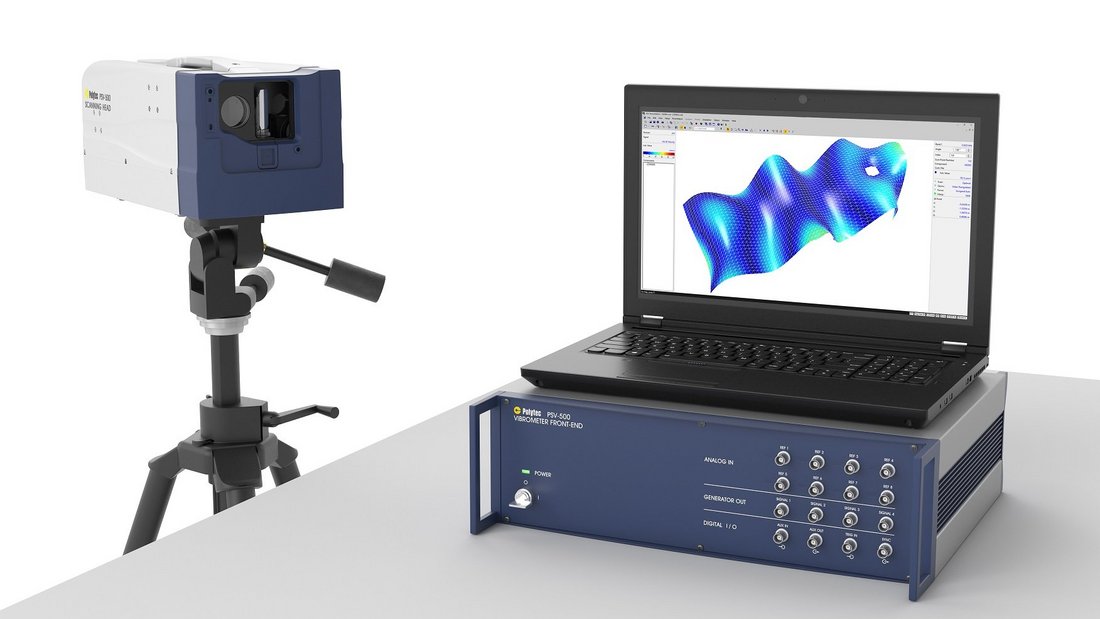

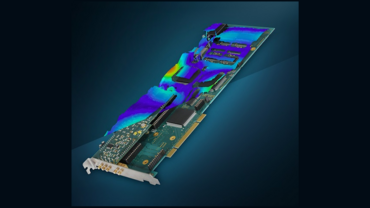

Safety is the top priority in aircraft construction. With each generation of new engines developed, the fuel efficiency must be increased. Safety and efficiency also starts with the durability properties of the smallest component: the turbine blade. 3D laser vibration analysis allows fast, efficient and highly detailed assessment of stress and strain distribution with basically unlimited measurement points and a high spatial resolution, using the fine laser spot. Derived directly from the FE grid and purely visual in nature, the instrumentation costs per blade are omitted entirely. The high spatial resolution reliably shows you both the location and the value of the maximum stress value. This method is used the world over by all the leading component and engine manufacturers. Following the trend toward a lighter engine, blisks (blade-integrated disks) are used in high-pressure compressors. Coordination of the blades’ eigenfrequencies is absolutely essential for safe operation. Scanning Vibrometers quickly provide you with the necessary data for this very purpose.

Polytec Magazine

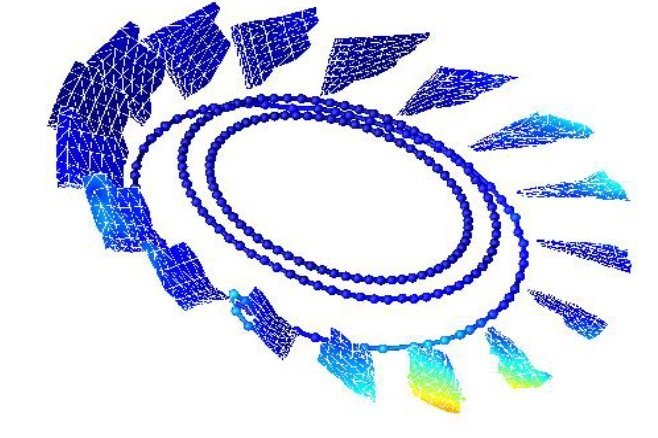

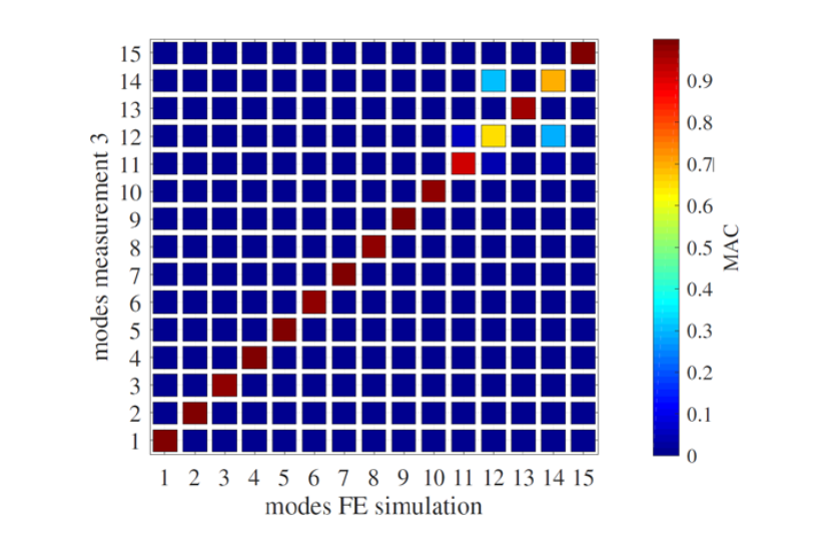

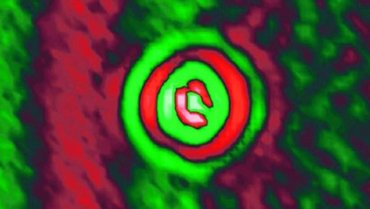

FE model correlation of a blisk

3D scanning laser Doppler vibrometry for fuel-efficient turbines

Optical stress and strain measurement for blisks and turbine blades

Bladed disk (so called blisks) or bladed rotors change their dynamic properties depending on the rotational speed. The optical derotation method is perfect if the calculation is to be adjusted using valid test data. With the measuring laser’s movement being synchronized with the turbine, one can easily extract the true operational deflection shapes from the trial. Even today, optical measuring technology is the established global tool for safety and a faster time to market in development, testing, preventive maintenance and even parts reconditioning.