Production metrology for metal processing

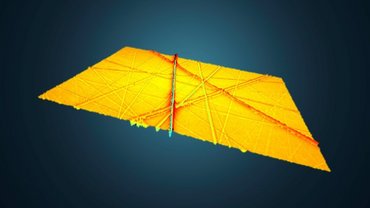

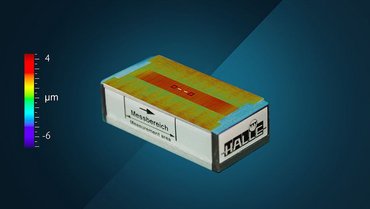

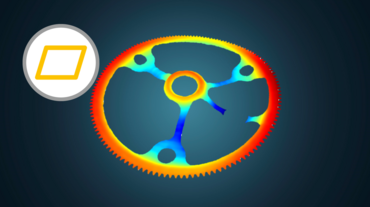

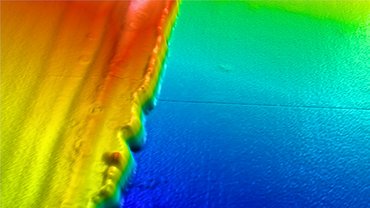

Surface quality in the micrometer and sub-micrometer range plays a key role in the lifecycle of products made from metal. Particularly for functional surfaces, compliance with tolerances is crucial to ensuring the subsequent products’ reliability and durability, even at the raw materials production stage. Surface measurement systems from Polytec offer you contactless measurement results with micrometer and nanometer resolution that can be reproduced at any time for precisely this purpose. While you can use the chromatic confocal sensors to analyze roughness profile lines as 2D parameters, you can use the TopMap large-field-of-view systems to areally detect form deviation and to characterize surface function and quality based on surface parameters such as flatness, ripple and parallelism even in 3D. The 2D measurement data is evaluated in line with DIN ISO 4287 / 4288, while the 3D measurement data is evaluated according to DIN ISO 25178.