MEMS prototype testing & prototype verification for process optimization

MEMS prototype testing and the verification of MEMS performance, whether in capped or uncapped MEMS devices is the core project step in the development of any new MEMS (microelectromechanical system. New MEMS devices always require a new production process, unlike with pure semiconductor devices. Process recipes and modules have to be revised at the very least, since at present you still can’t fall back on standard recipes for new micromechanical components, as is otherwise customary in semiconductor development.

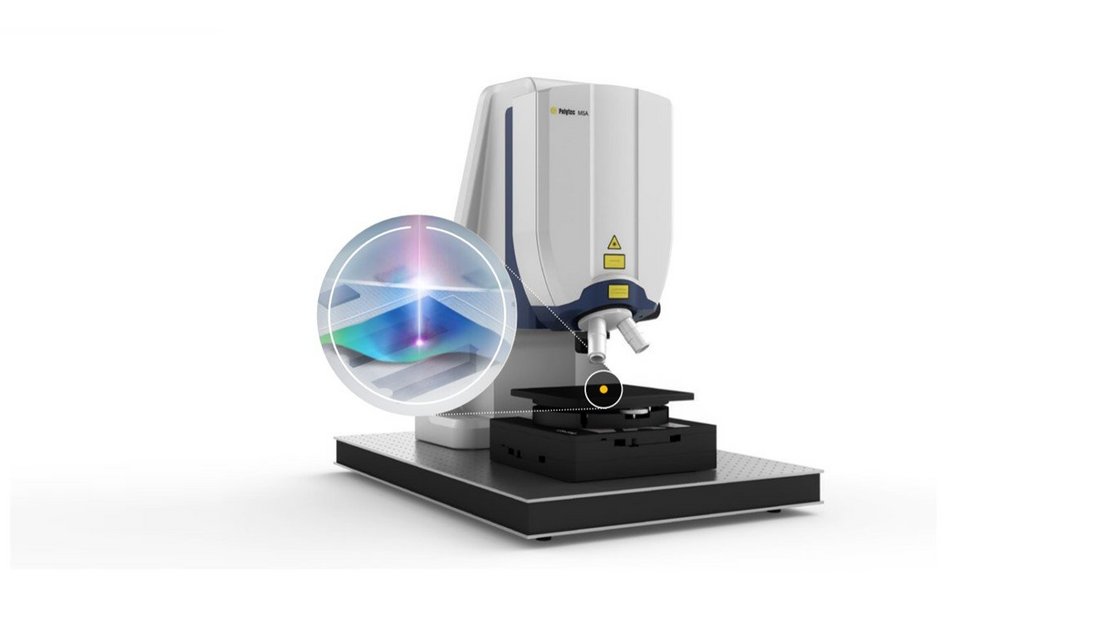

Both the system design and an optimized process design are essential if a structural element determined primarily by mechanical properties is to work properly. MEMS prototype testing and MEMS prototype verification thus not only enables the design to be confirmed, but allows for affirmation of the manufacturing process, too. In order to determine unexpected mechanical behaviour and model deviations, the powerful optical measurement by laser vibrometry often is the method of choice.

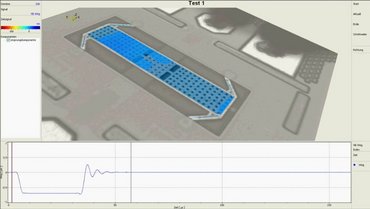

Prototype testing of CMOS / MEMS co-integrated flow microsensor

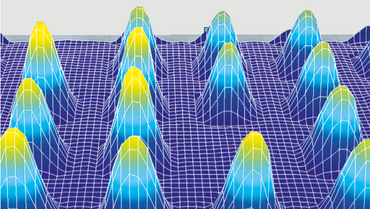

Due to its high frequency bandwidth, high lateral resolution and excellent amplitude resolution, Polytec laser vibrometers are reliable measurement tools for reliable determination of the MEMS modal properties such as MEMS transfer functions, MEMS resonance frequencies, damping and deflection shapes. The topographical analysis of MEMS as one part of MEMS prototype testing is also important for component development and process optimization. Surface measurement data such as step heights and other form parameters provide valuable information about current process parameters, leading to a reliable quality control of the MEMS manufacturing process.

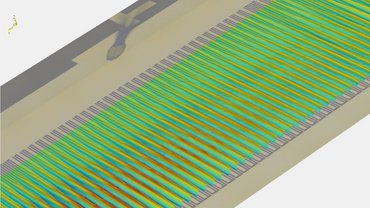

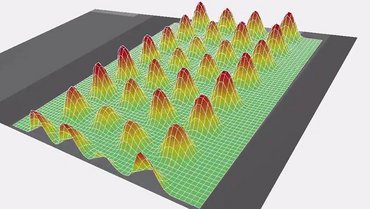

The figure illustrates the areal characterization of the topography of a CMOS / MEMS co-integrated flow microsensor carried out using the surface topography option of the MSA Micro System Analyzer from Polytec. The flow microsensor had been realized using silicon-on-insulator (SOI) technology.