Contactlessly characterizing SAWs

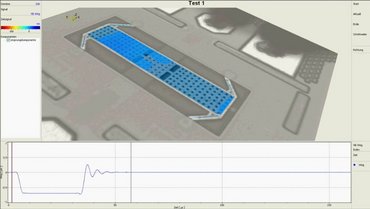

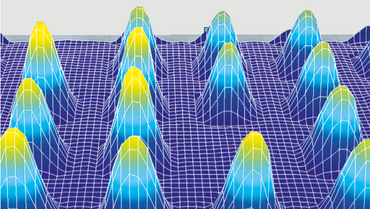

As surface acoustic wave (SAW) filters are electronic components that work through surface acoustic waves they are in fact mechanical filters. Due to their superior properties, they are an integral part of high-frequency applications such as mobile telephony. Optimization of the SAW surface’s micro-acoustic properties is one of the key tasks involved in developing new SAW components.

Due to the high frequencies, short acoustic path lengths and small vibration amplitudes, the measurement and visualization of surface waves places particular demands on measuring technology. Using a laser vibrometer is one of the few solutions available for measuring vibration on such systems.

Polytec’s laser Doppler vibrometers enable you to conduct non-contact characterization operations across all frequencies, even when faced with broadband excitation. The deflection shapes are visualized in an impressive way. You can even examine transients and relaxation behaviour. Key results are determining properties such as the filter characteristics and performance losses (leakage).

Polytec Magazine

Selective polarization conversion of surface acoustic waves

A new driving mechanism for acoustofluidics

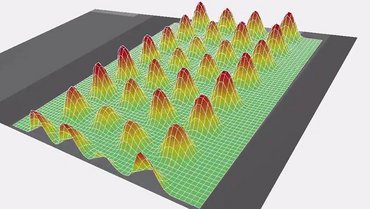

Testing SAW at development stage at high frequencies

In addition to their use as electronic filters, SAWs play a key role in microfluidic applications too. In this regard, SAWs are used for targeted droplet manipulation of biomaterials. When such lab-on-a-chip components are being developed, the surface dynamics are examined with high-frequency vibrometers like from the Polytec MSA Micro System Analyzer series due to their non-contact optical measurement, the wide frequency bandwidth and the high resolution.