Reliable surface quality inspections and pass-fail analysis

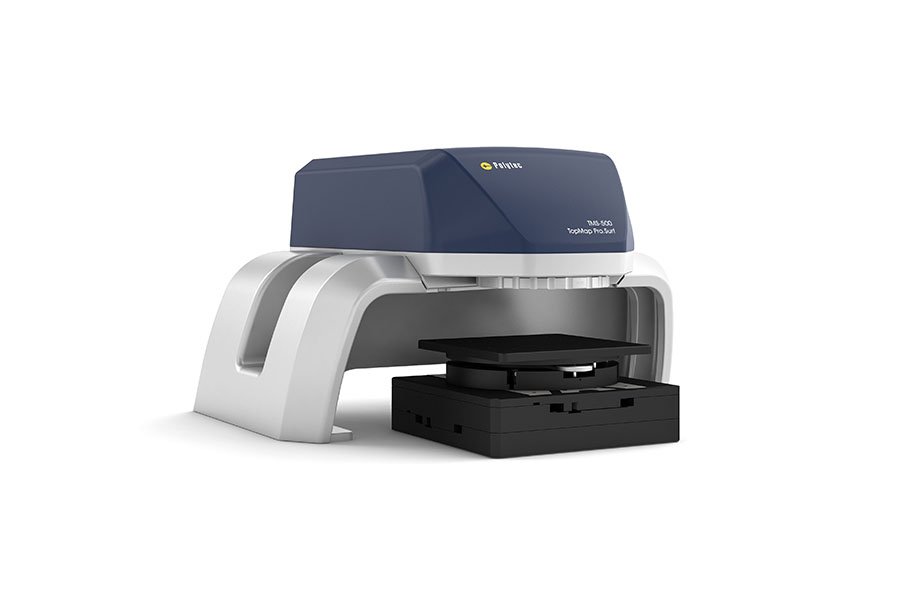

The TopMap Pro.Surf quickly, reliably and precisely determines form deviation. TopMap Pro.Surf, the high-end solution, is ideal for measuring precision-made surfaces – in the metrology chamber, close to production or even right on the production line thanks to a high level of repeatability. The TopMap Pro.Surf offers the customized solution for all surface characterization requirements using parameters such as flatness, step heights and parallelism. All in all, the spatial resolution, the telecentric optics and the outstanding speed and performance cut a very impressive figure indeed.

Highlights

- Quick and precise 3D surface characterization

- Non-contact measurement principle and traceable measurement results

- Smart Surface Scanning technology and filter wheel for almost all surfaces

- Large measurement volume of 230 x 220 x 70 mm³

- Telecentric lens measures even low-lying points

- Safe sample handling thanks to a long stand-off distance

- Automatic component recognition without any need for mechanical mounting

- Easy-to-use and automatable measurement and analysis software