Non-contact measurement of speed and length for production control

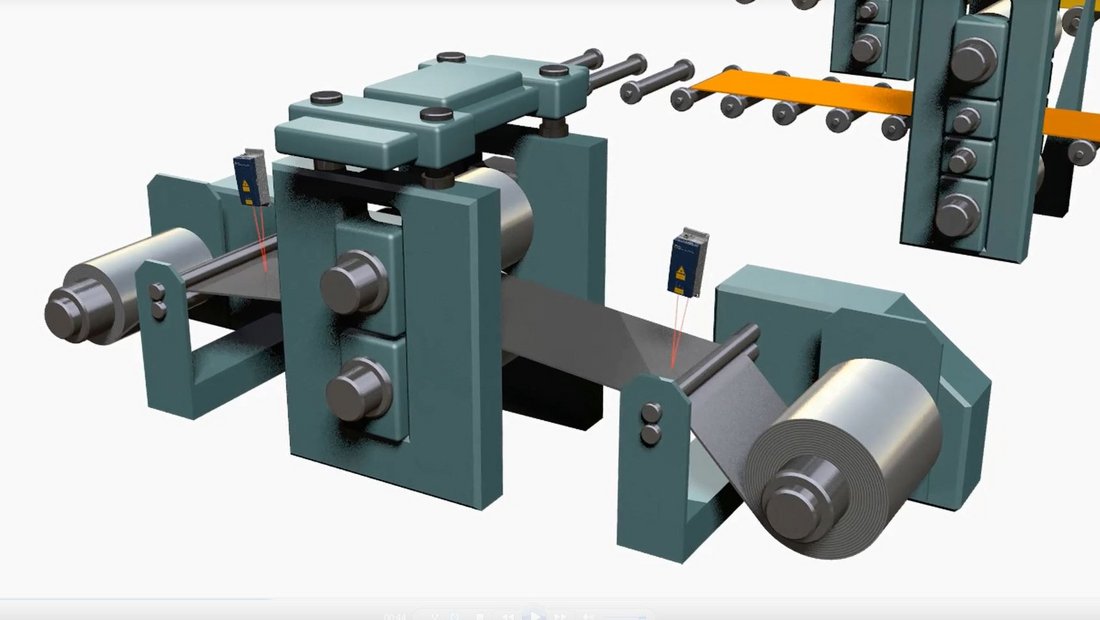

In the production of strip and sheet material, continuous material as well as piece goods, for example in steel or paper mills, knowing the exact strip length and current process speed is essential for keeping costs low and optimizing quality and yield. LSV (Laser Surface Velocimeters) from Polytec are optical sensors for the precise in-line monitoring of length and speed in production processes. The laser sensors measure in a non-contact way, providing precicion measurements on any material - no contact, no slippage, no wear. Avoiding any influence on the measured material, these non-contact encoders works reliably even in harsh production environments, in cold and hot temperatures. The latest generation ProSpeed® LSV length and speed sensors impress with maximum precision and reliability, featuring a 3-year warranty and custom service options tailored to your process control.

Need more info, onsite demo or personal support?

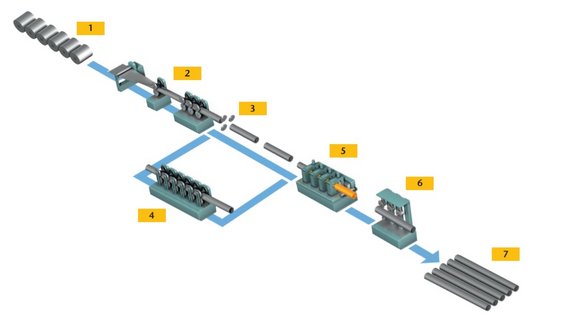

Sensor solutions for tube & pipe production

Accuracy, versatility and reliability make the LSV Laser Surface Velocimeter the perfect sensor solution throughout the tube and pipe industry where precise, real-time speed and length data are critical. In addition, the optical sensors cut down production costs by minimizing material scrap and by optimizing product and process quality. Where to implement laser sensors in manufacturing processes of tubes and pipes?

Environmental commitment according to ISO 14001

We at Polytec proudly announce our certification according to both ISO 14001 and ISO 9001. These certifications reflect our strong commitment to quality and to our environmental responsibility – cornerstone of our continuous improvement process. Thanks to our team and external partners for their dedicated support!