Why Polytec for optical surface metrology

Polytec has decades of experience in surface metrology and designing white light interferometers. We Polytec optical profilers combine advanced white-light interferometry with robust optical designs to deliver reliable 3D surface data—in the lab and on the shopfloor. You benefit from:

What this means for your surface metrology tasks:

Optical profilometers designed for real applications — from microscope-based systems for microstructures to telecentric solutions for large-area form measurement

Proven measurement expertise through feasibility studies and contractual measurements on customer samples

Reliable results beyond the lab, supported by robust system design, environmental compensation, and automation-ready concepts

Global service and long-term partnership, including training, customization, modernization, and a 4-year warranty

Flexible access models, from demos and feasibility checks to rental, leasing, and measurement-as-a-service via PolyFlex

Optical surface metrology: From microscope-based to telecentric systems

Choose the profiler type that matches your scale, workflow, and precision requirements. Whether you work on micro-features or large mechanical components, Polytec offers the right optical technology for reliable 3D topography.

Micro Profiler

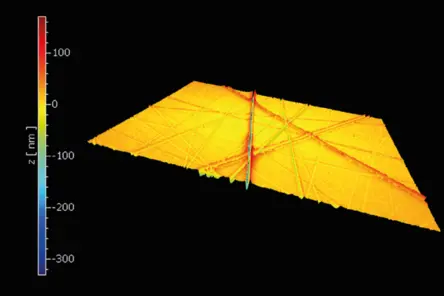

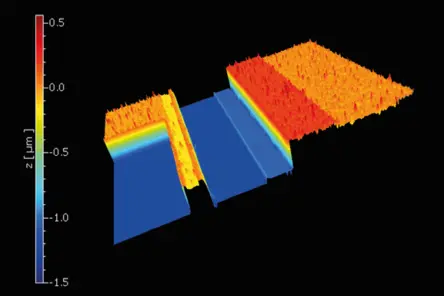

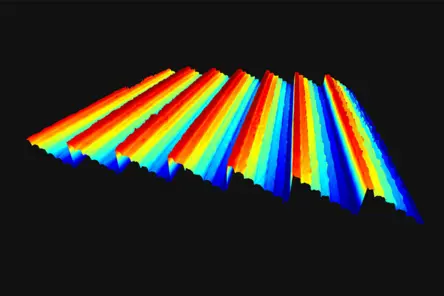

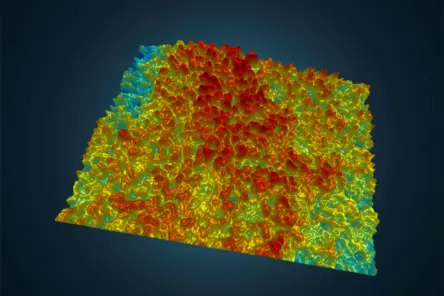

Micro.View systems are optimized for ultra-high-resolution measurements in the sub-nanometer range. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

Macro Profiler

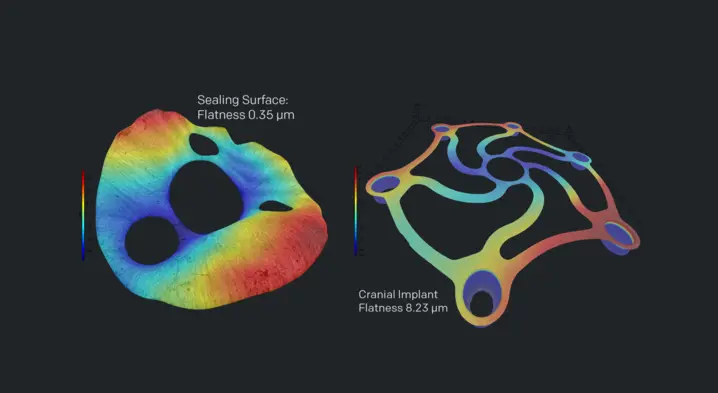

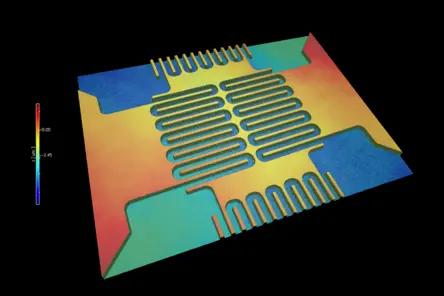

Pro.Surf systems enable fast, area-based 3D topography measurements with telecentric optics. They support reliable inspection of flatness, shape, parallelism and step heights across wide fields of view and in-bore features.

Metro.Lab

Metro.Lab is a compact, wide-area surface profiler. It combines high measurement performance with a small footprint—ideal for space or budget conscious applications that still require reliable 3D surface data.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

Operate your metrology task—easy, precise, repeatable

Optical surface metrology covers a wide range of functional parameters—from roughness and texture to flatness, step height, thickness and tribology. Explore below some metrology jobs, conducted by our customers or in our application labs as a contractual measurement.

Choose the right surface profiler with confidence—get a demonstration of our capabilities.

Typical measurement tasks in surface metrology strategies

Service & support that keeps your metrology running

Your metrology results only matter if your system performs reliably every day. Polytec supports you throughout the entire lifecycle — from first feasibility checks to long-term maintenance, upgrades, and flexible access to systems via PolyFlex.

- Feasibility & consulting to define the right setup before you invest

- Contract metrology (PolyMeasure) for fast expert results

- Commissioning, training & enablement for a smooth, confident start

- Calibration, maintenance & repair to ensure long-term accuracy

- Modernization & upgrades to keep your system future-ready

- PolyFlex options (rent, lease, measure-as-a-service) for maximum flexibility

Choose the right surface profiler with confidence—let us run a feasibility study with your sample.

Deepen your know-how in optical surface metrology

Explore practical guides, standards explanations, and technology insights that help you understand, compare, and apply optical surface metrology — whether you’re evaluating systems or improving your process.

Surface parameters

Learn more about roughness, flatness, step-height and layer thickness.

ISO 21920 roughness

ISO 21920 is the new standard for mechanical engineering, design and roughness specifications

"Try before buy" offer

Measure, rent, decide - on your terms. Make a confident decision about which surface profiler fits into your metrology strategy and safeguard your capital investment.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.