Developing ultrasonic devices with maximum reliability

Safety is the top priority in medical technology. Consequently, complete documentation of the development stages is indispensable for producing good products and providing legal certainty. Laser vibrometers are therefore extremely important in the development and quality assessment of medical instruments, such as dental or surgical ultrasonic devices and imaging methods. The efficiency and safety of health care products, such as inhalators, respirators and toothbrushes, can all be improved by carrying out measurements with Polytec vibrometers. Laser vibrometers have also become indispensable for the development, inspection, calibration and certification of middle ear implants and implantable hearing aids.

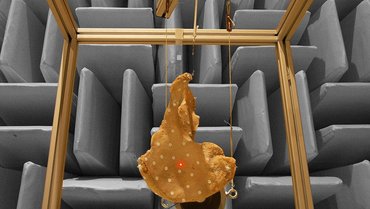

Ultrasonic energy has to get to where it’s needed in medical devices. Polytec’s PSV Scanning Vibrometer quickly and clearly illustrates how energy is distributed by ultrasonic actuators and thus speeds up the development process. Localization of a particular operating frequency’s vibration nodes allows you to optimize the design and thereby reduce energy dissipation. Thanks to the high spatial resolution and measurement accuracy in the picometer range, high-frequency deflection shapes are quickly and reliably visualized too.

Polytec Magazine

Improving dental healthcare

Keep healthy teeth with ultrasonic scaler using EMS Piezon NO-PAIN technology

FE model validation of ultrasonic medical instruments

Laser vibrometry is the decisive key technology in the design and development of medical ultrasonic instruments. It is the ideal tool for verifying FE simulations – both for invasive and diagnostic medical ultrasonic instruments. Thanks to its linearity well into the high MHz range and the complete lack of feedback effects, coupled with high lateral resolution, this technology is suitable for nearly all structural dynamic tasks. Calculation methods derived from the basic technology for sound field visualization and for durability (strain / stress) open up further applications. Consequently, laser Doppler vibrometry is a tool suited to the development of efficient, reliable and effective instruments for the doctor and the researcher.

Laser vibrometry focusing on the small details

Characterize small and delicate structures in a non-contact way. Analyze vibration, acoustics and dynamics. Measure biomedical samples, electronics components and microstructures like MEMS by light, without mass-loading, and from DC up to the GHz range on a large bandwidth. Laser vibrometers focus on the small details, measuring deflection shapes for model validation. They assess the frequency response and determine resonance frequency, impulse response and Q factor. No matter how big or small – Polytec vibrometers measure it!