Visualizing surface waves with high resolution

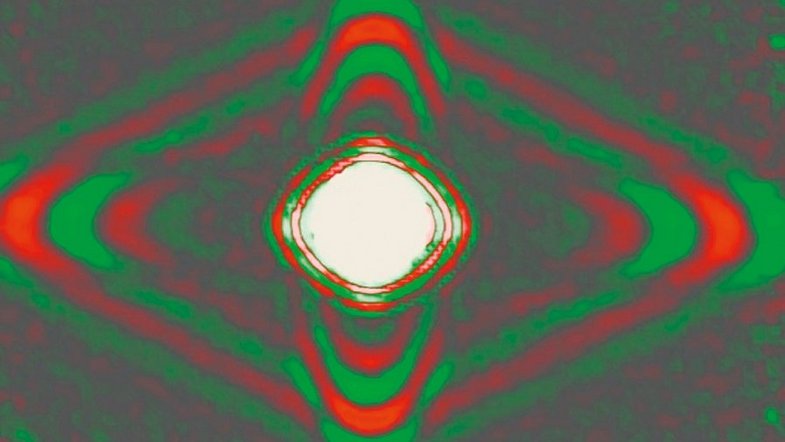

When it comes to fiber-reinforced composites, it is key to detect and localize damage such as delamination or cracks at an early stage – both in production and during operation. Lamb waves are surface waves propagating on thin plate structures that play the major role in non-destructive materials testing (NDT). Lamb waves interact with different types of material faults, thereby making them visible. Lamb wave based material testing is increasingly gaining in significance – particularly in the maintenance of lightweight design like modern aircrafts, where fiber-reinforced composites (CFRP) are increasingly being used.

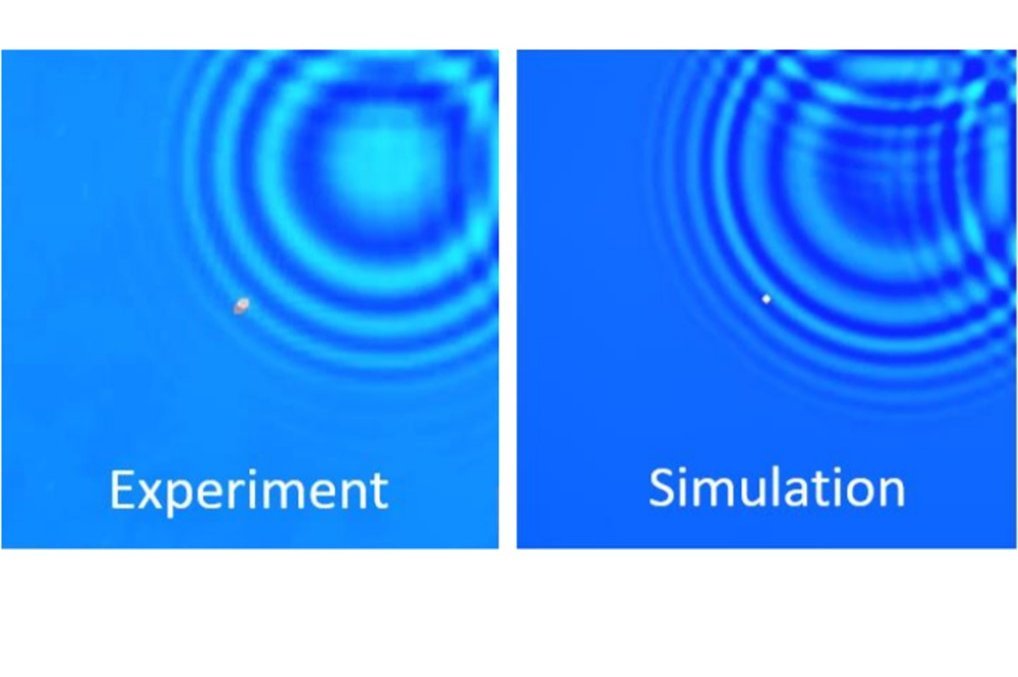

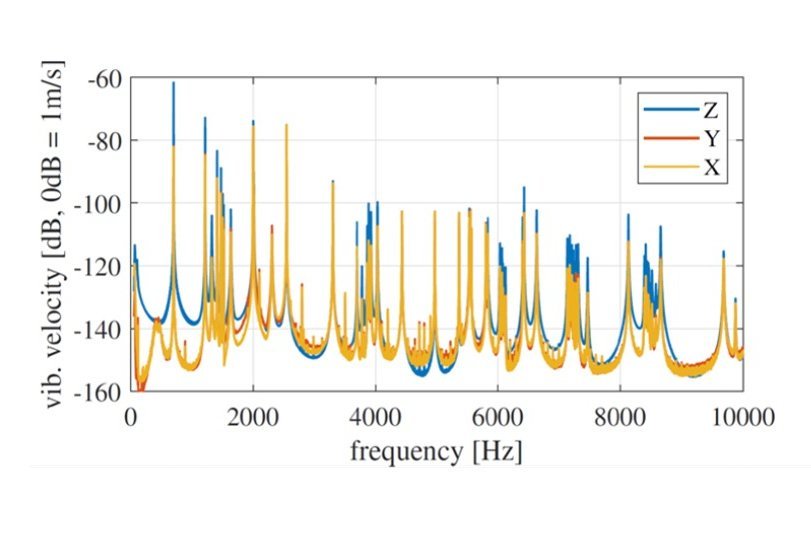

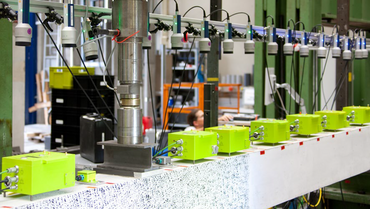

The non-contact PSV Scanning Vibrometers visualize temporal propagation of Lamb waves with high spatial resolution. Monitor the entire 3D vibration vector for each scan point, so the typical S and A waves that are primarily described as in-plane and out-of-plane waves are broken up during the analysis. Laser vibrometers are thus indispensable as tools for researching Lamb waves and developing methods that are suitable for industrial purposes.

Lamb waves revealing structural defects

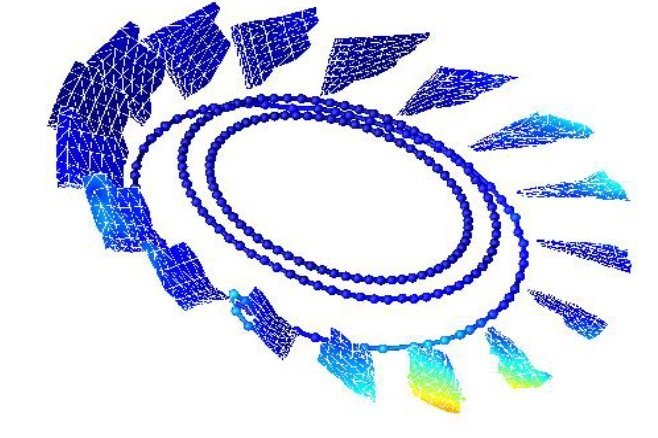

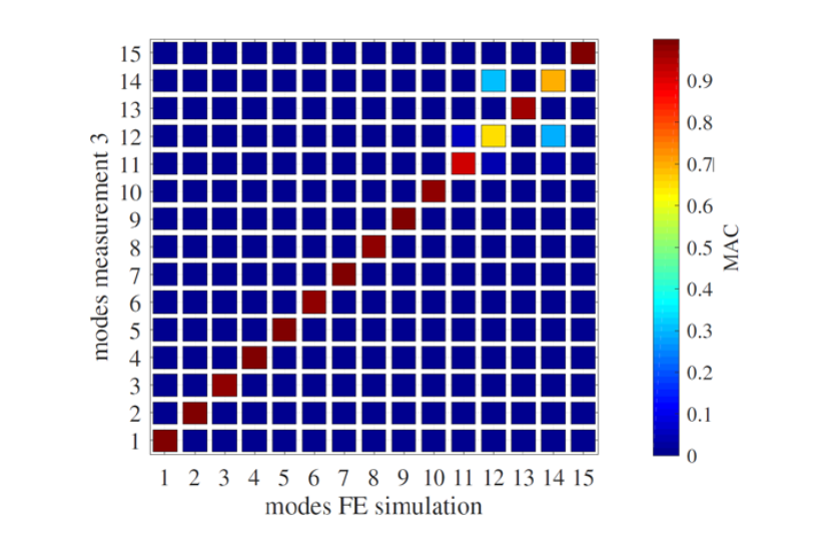

Polytec Scanning Vibrometers are therefore also suitable for designing component-integrated sensor networks, which are increasingly being used in critical structural elements, including aircraft, so as to continually monitor them during operation (structural health monitoring). In such situations, a multitude of vibration sensors are permanently integrated in a component, and their distribution is optimized so that structural damage on the component is reliably recorded by the sensors.