Securing functionality of lab-on-a-chip devices

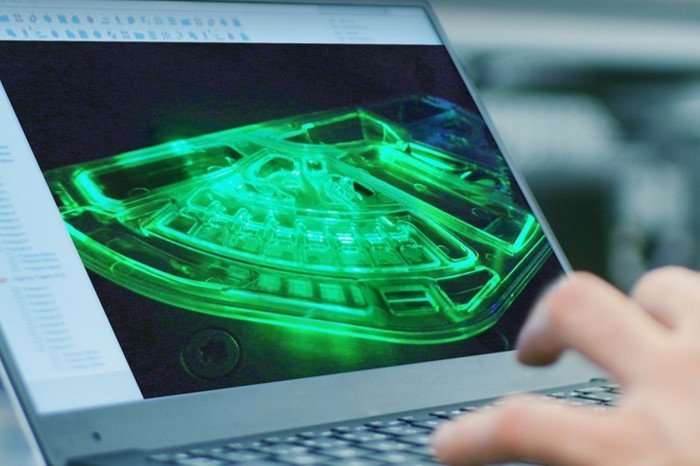

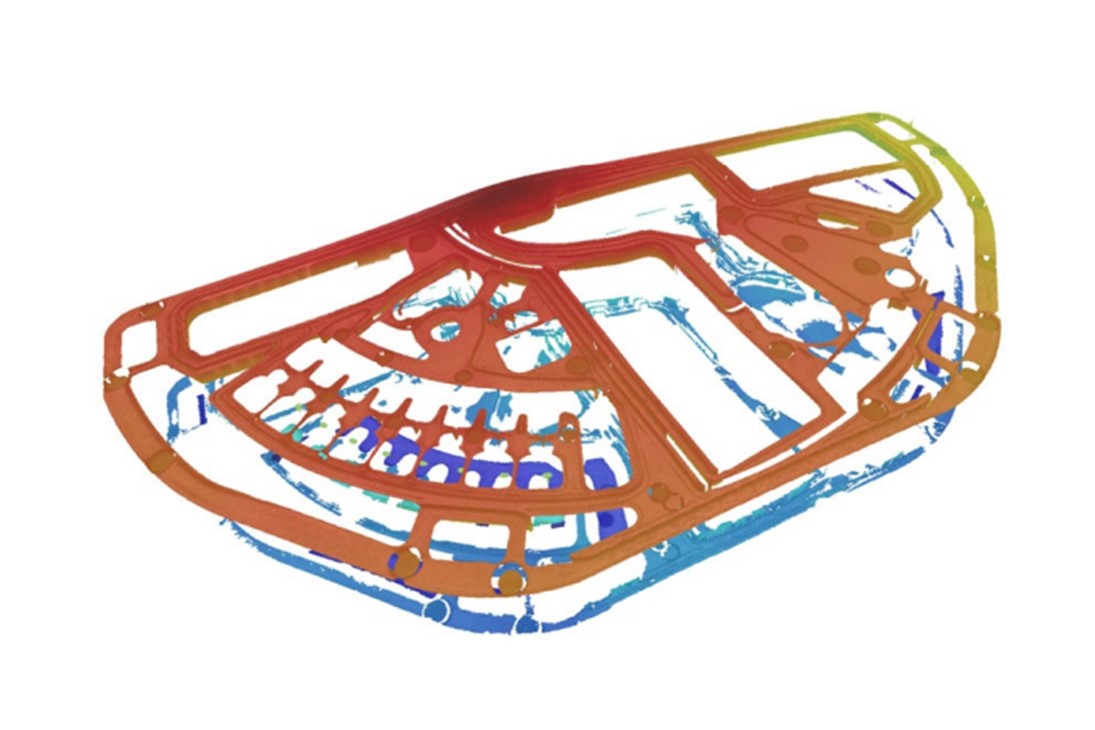

Microfluidic lab-on-a-chip systems, short for LoC, implement a multitude of ocurring processes on the smallest of spaces. Lab-on-a-chip enable the analysis of liquids on a compact chip for process analytics and online diagnostics of biological, chemical or physical processes. Lab-on-a-chip devices use the capillary force for transporting very small quantities of a fluid in the range of a few picoliters (pL) or microliters (mL). With non-contact measurement technology such as the TopMap 3D surface metrology, you can inspect the dimensional accuracy of the microfluidic channel of a lab-on-chip, evaluate the LoC channel depth or channel width with high precision, determine the volume or measure flatness over the entire surface of the lab-on-a-chip device. If parallelism, step height or flatness values of a lab-on-a-chip comply with the tight tolerances defined, this secures performance and reliability of your lab-on-chip process analytics.

Read the full interview

Raimund Rother, process engineer at Hahn-Schickard:

Applying the sealing film to the cartridges of our lab-on-a-chip is challenging: on the one hand, the demand of achieving a high seal strength without closing the fine channels of the cartridge during bonding. Secondly, production tolerances regarding the injection molding thicknesses cannot be eliminated completely, which has to be compensated when sealing. To adjust the sealing tool precisely, we measure the height levels of the cartridge using a scanning whitelight interferometer. This 3D measurement data then forms the basis for designing the sealing tool.