Optical inspection of PCB and BGA

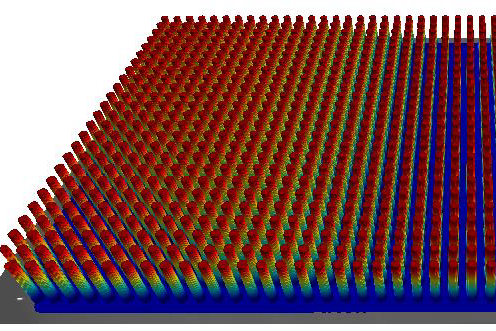

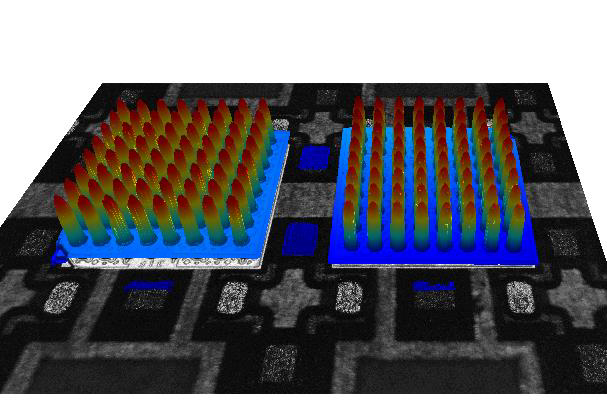

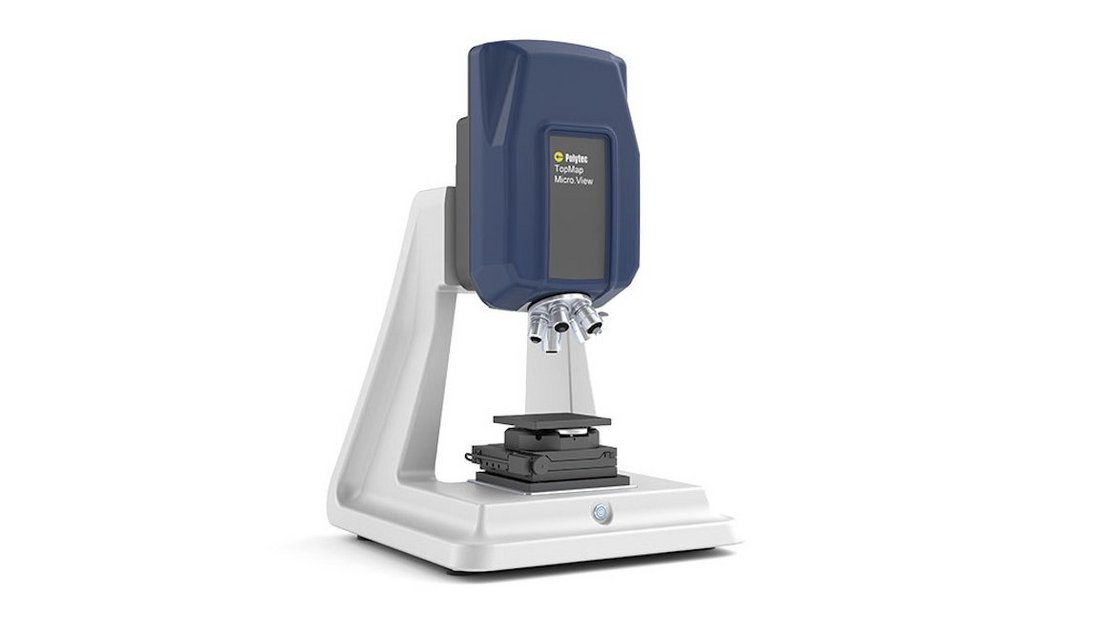

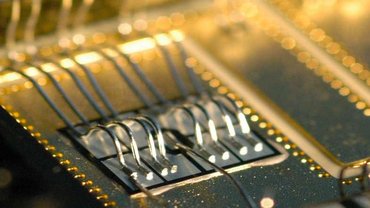

The reliability of PCB and the respective PCB components like IC (integrated circuit) or BGA (ball grid array) can vary with every design and selection of semiconductor components installed. For each type and series of PCB design, ideally automated, in-process quality control and testing of PCB is needed at manufacturing. In addition, at customer level for inspecting for “dead on arrival” issues, caused for example by breaking on weak points during transportation, quality control methods are part of the process. TopMap optical 3D surface metrology allow fast scanning of entire sample surfaces with nanometer resolution, providing areal topography data of PCB, IC and BGA in a single shot.

How do you control BGA quality?

What parameters do you measure on ball grid arrays?

3D profiling as quality inspection of ball grid arrays

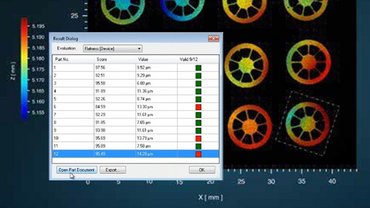

Using 3D optical profilers for areal and non-contact characterization can be powerful quality control tools: For measuring topography of electronic components, testing of printed circuit boards (pcb testing), solder bumps, ball grid array flatness measurement, pass-fail analysis and process trouble-shooting in the manufacturing of PCB. Providing valuable feedback for the production process of PCB and electronics, optical profiling can be an efficient integral part of the quality control process of electronics and micro-electronics. Usually, more advanced and complex PCB are applied and designed layer by layer which might require layer thickness measurement and distinguishing several layers. Here, optical testing solutions from Polytec open up a realm of solutions for measuring layer thickness as one quality indicator.

For characterizing PCBs for failure analysis, checking BGA flatness in a non-contact way, for free feasibility studies and a first sample report, contact us.