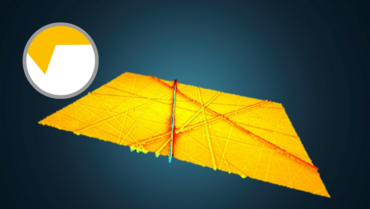

Non-contact, areal characterization of surface form parameters

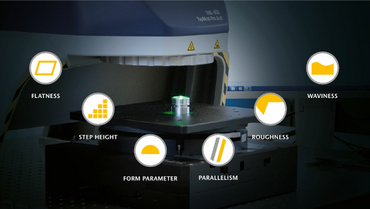

Product requirements in precision engineering – responsible for precise motion, improved service life, low wear, better packing densities and so on – for the most part go hand in hand with surface properties. Generally speaking, surfaces differ slightly in terms of size and form and satisfying the functional requirements, which is why even designers allow for a certain degree of variation. Now, analyzing surface properties becomes way easier using large-area measuring white-light interferometers like the Polytec TopMap sensor systems. Measure several samples at the same time, benefiting from automatic sample recognition and the large measuring field, and implement routine inspections by saving and loading pre-defined measurement recipes with Polytec's specific user interfaces for efficient production-testing.

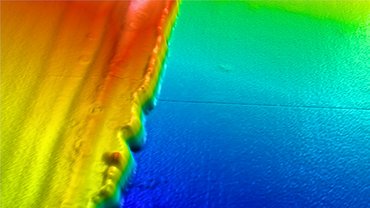

A practical example

A certain degree of form variation is welcome when it comes to microdrives, so that the desired freedom of movement is guaranteed.