Next generation optical surface profiler

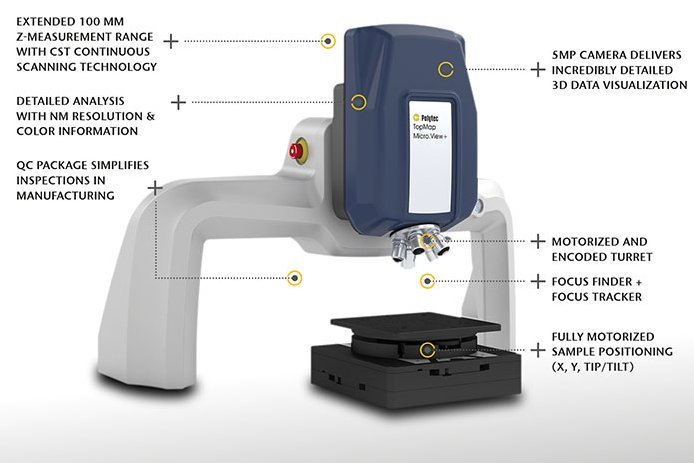

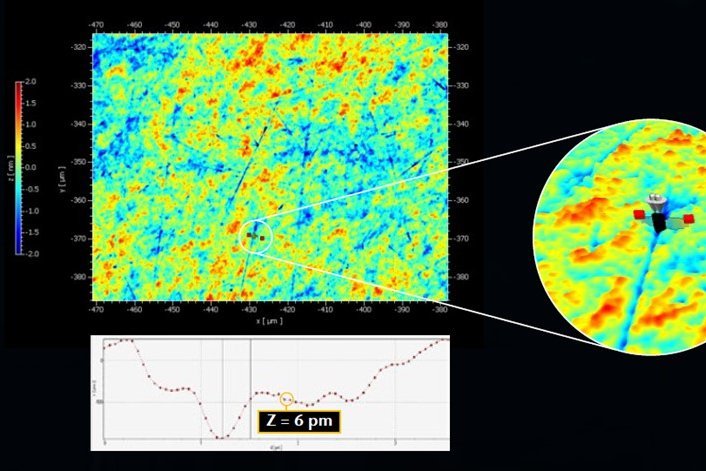

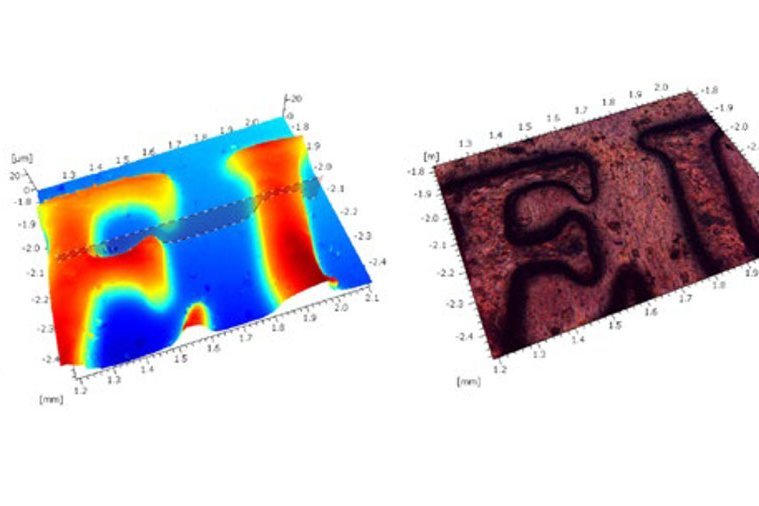

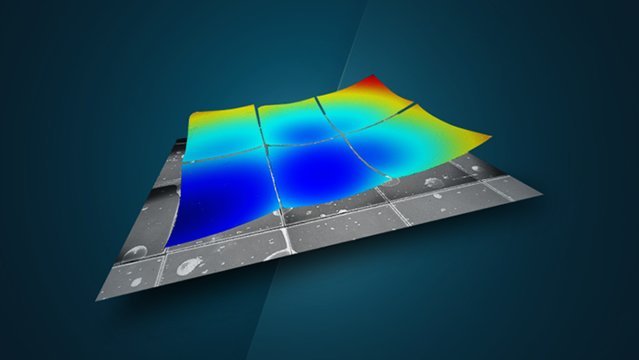

TopMap Micro.View+ is the next generation optical surface profiler. Designed for modularity, this comprehensive workstation allows for customized and application-specific configurations. The Micro.View + delivers the most detailed analysis of surface roughness, texture and microstructure topography. Combine 3D data with color information for amazing visualizations and extended analysis like detailed documentation of defects. The high-resolution 5 MP camera delivers incredibly detailed 3D data visualization of engineered surfaces.

Highlights

- High-end white-light interferometer with nm resolution

- 100 mm z measurement range with CST Continuous Scanning Technology

- With Focus Finder and Focus Tracker ready for automation

- Motorized X, Y, Z, tip/tilt and turret save repositioning

- Color information mode for extended analysis and documentation of defects

- Modular, application-specific configurations

Precision measurement is about experience, about expertise and about experts and technology we trust in. Take a look behind the scenes, learn more about the development and about the people behind TopMap and meet the PolyXperts. Come join our journey!