Highlights

- Cost-efficient and demand-oriented use of the latest measuring equipment and laboratories w/o investment

- Video conferencing allows remote testing services

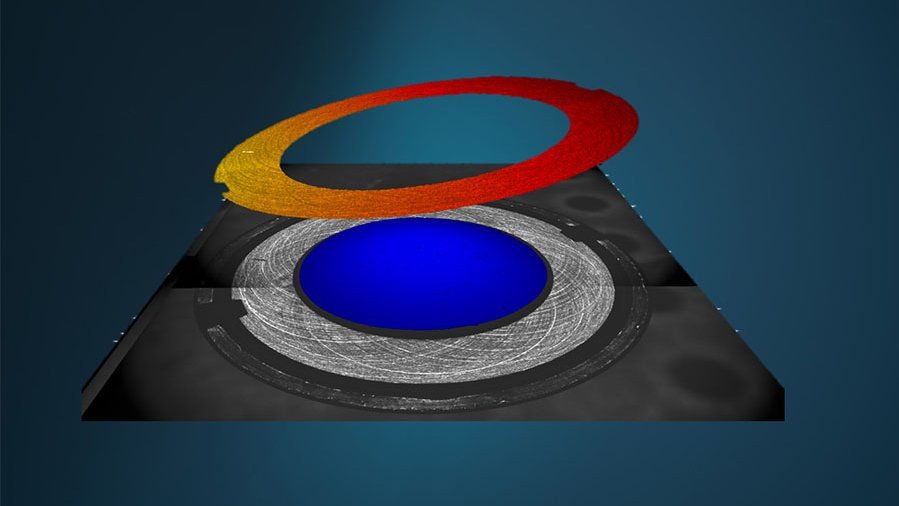

- Non-contact, traceable measurement of both tiny microsystems <1 µm and larger precision mechanics

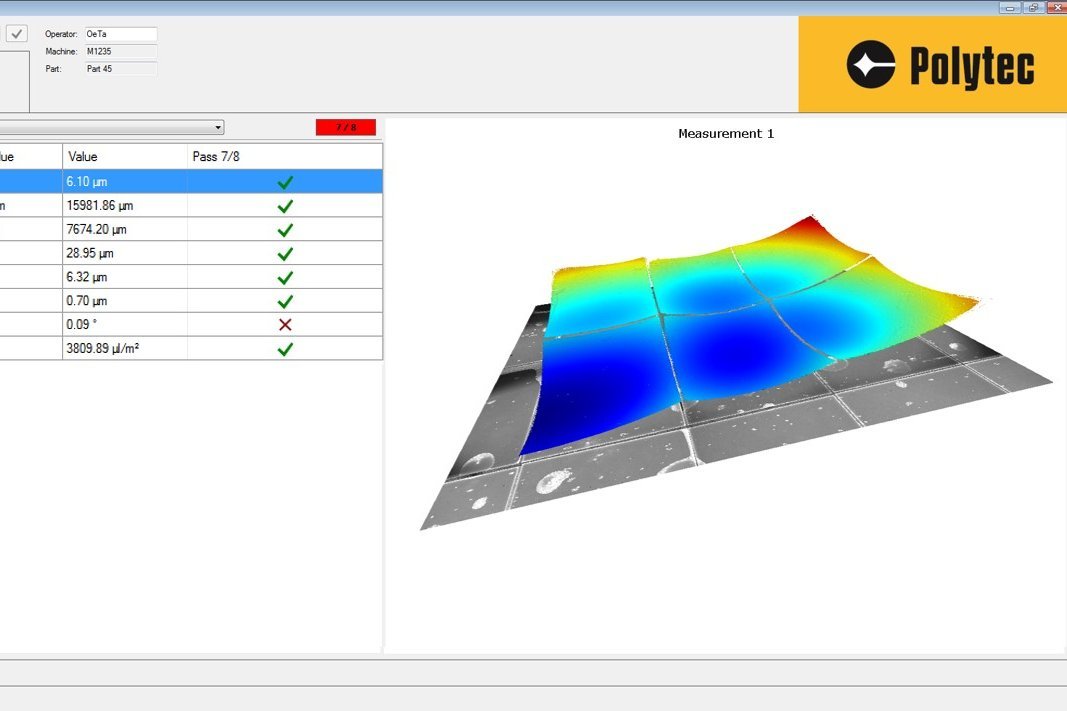

- 3D topography reliably measures form parameters such as step height, parallelism, flatness and roughness with high precision

- Upon request even vibration-isolated test setups for inspecting microsystems and MEMS

- Measurement principle works even in electromagnetic fields, on all materials including biological samples

Typical applications

In the field of high resolution non-contact 3D topography measurements, see these typical applications:

- Verification of form deviations on micro and nanometer scale, e.g. for sealing surfaces with very detailed expectations regarding pressure and leakage, flatness, roughness and waviness

- inspection of large samples with large field of view up to 45 x 34 mm in a very short time even without stitching

- evaluation of surface finish providing a large number of ISO parameters for roughness and waviness

- characterization of friction surfaces regarding wear resistance using the material ratio curve

- evaluation of the surface finish quality e.g. measurement of roping for aluminum sheets

- detection of undesired warpage of functional surfaces like electronics boards or circuits

- measurement of step heights and parallelism of surfaces with large height difference up to 70 mm

- thanks to the telecentric optical design, surface inspection in hard to access areas and deeply recessed surfaces such as depressions and bores