Cut length control on roll-fed material

Determining the length and velocity provides the basis for controlling the cutting length. If the sheet materials are not to be stopped in order to perform the cut, then the cutting device must move along with the sheet material for a straight cut, in other words it should be a "flying cutting device". The speed of the sheet material is measured for velocity synchronization

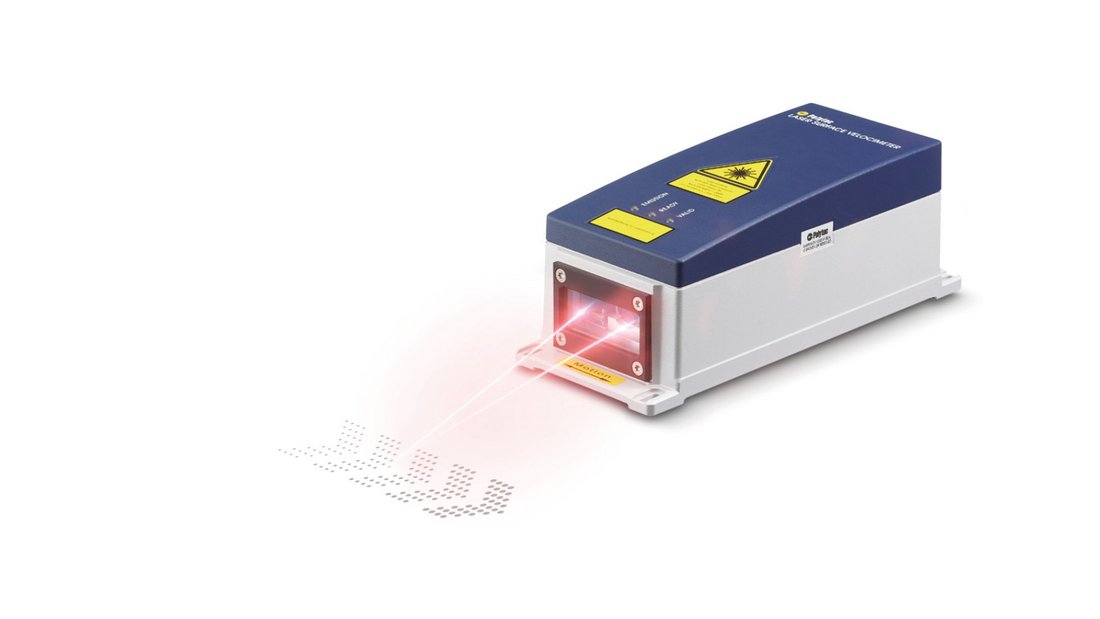

Laser surface velocimeters (LSV) from Polytec are ideally suited for cut length control because they measure both velocity and length at the same time and can display the values on different interfaces. The LSVs work on almost any surface and they are not susceptible to contaminated surfaces. The non-contact measuring technique makes it possible to eliminate any negative influences on accuracy, such as slippage and wear, simultaneously. The product being subjected to the measurement alsoremains intact .

The Polytec LSV offers increased cutting precision compared to other methods and therefore allows the safety margins added to the preset cut length to be reduced. This will save costs on every cut. Another benefit of Polytec systems is the flexible interface concept – it enables length and velocity readings via encoder output, serial interfaces, LAN, Profibus and Profinet. The digital outputs feature a pre-warning signal that indicates when the cutting length is about to be reached, as well as the cut signal for triggering the cutting process.

Polytec Magazine

Building the perfect roof

Controlling the length cutting of the trapezoidal sheet metal profiles

Control cut-length reliably

- Control of torch cutters in continuous casting

- shear control in metal service centers

- control of flying shears in bar mills

- cut length control in section rolling mills

- saw control in tube rolling mills

Rotary tube saw control

These are increasingly being used in tube rolling mills. The saw blade is moved around a circular course at the speed of the tube. The movements must be exactly synchronized and that with speeds of up to 10 m/s. The Polytec LSV measures tube speed without slippage or wear to control the rotary tube saw. Using the LSV allows for an exactly vertical cut and reduces the length tolerances to a minimum.