Velocity difference measured with laser precision

In processes which involve the elongation of products any desired velocity difference should be appropriately regulated . In other processes differences are undesirable since they can lead to backlogging or may even damage the product – due, for example, to the slippage of drive rollers or because tension is generated in the product. The velocity difference is calculated by measuring the velocity at different points in the process and comparing the readings with one another.

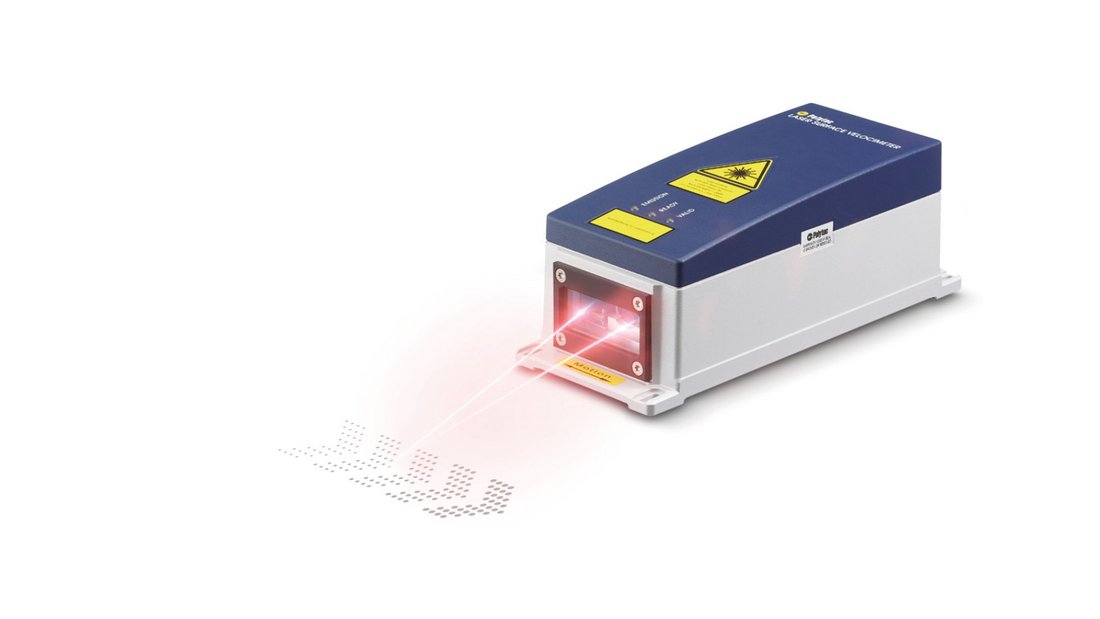

Using several laser surface velocimeters (LSVs) allows you to accurately determine the velocity at the relevant points in the process, thereby enabling you to optimize it. ProSpeed LSVs from Polytec are ideally suited because they can conduct measurements on almost any surface and they are not susceptible to contaminated surfaces. The non-contact measuring technique makes it possible to eliminate any negative influences on accuracy, such as slippage and wear, simultaneously. The product being subjected to the measurement also remains intact. As the measurement is free of slippage you can control the process to ensure high reliability, even during start-up processes and right up until deceleration, thereby increasing product output. The increased accuracy of velocity measurement allows you to monitor the velocity differencemore closely. As a result you are better able to adhere to the end product requirements. The result: You increase quality while at the same time reducing waste.

Speed measurement in c frames of rolling mills

The metal processing industry has high standards when it comes to the dimensional accuracy and quality of steel and aluminum products. Modern rolling mills are now frequently controlled using the mass flow principle to further reduce the thickness tolerances of rolled strips. Laser surface velocimeters (LSVs) are easy to integrate and enable reliable measurement of the velocity component.

Synchronizing speed in aluminum fabrication

In the largest aluminum smelting and rolling plant in the world, the length and velocity of aluminum sheets in the manufacturing process are measured simultaneously using non-contact laser Doppler measurement technology from Polytec. Several Polytec LSVs are integrated in the manufacturing process and provide readings for plant control.

Measuring differential speed in-line

Polytec LSVs are used for a variety of velocity difference measurements in the metal industry:

- in reversing and tandem mills for mass flow regulation in cold-rolling mills,

- skin-pass and stretch degree calculation in skin-pass and/or stretching mills,

- with a high temporal resolution for roll gap control in tailored blank flex rolling mills

- synchronization for welding control