Amplitude and frequency as key indicators for quality control

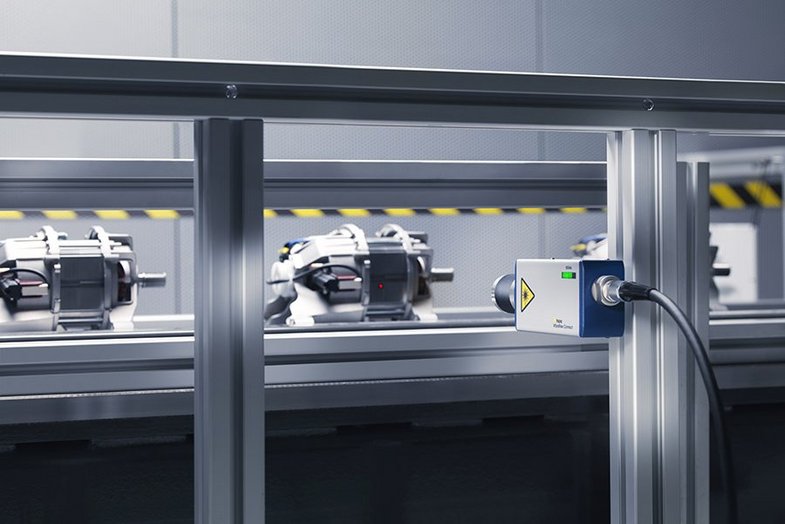

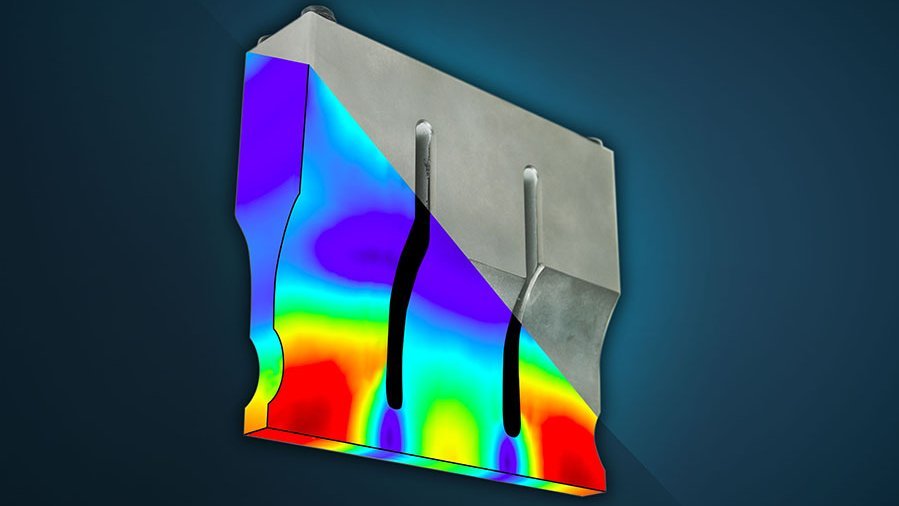

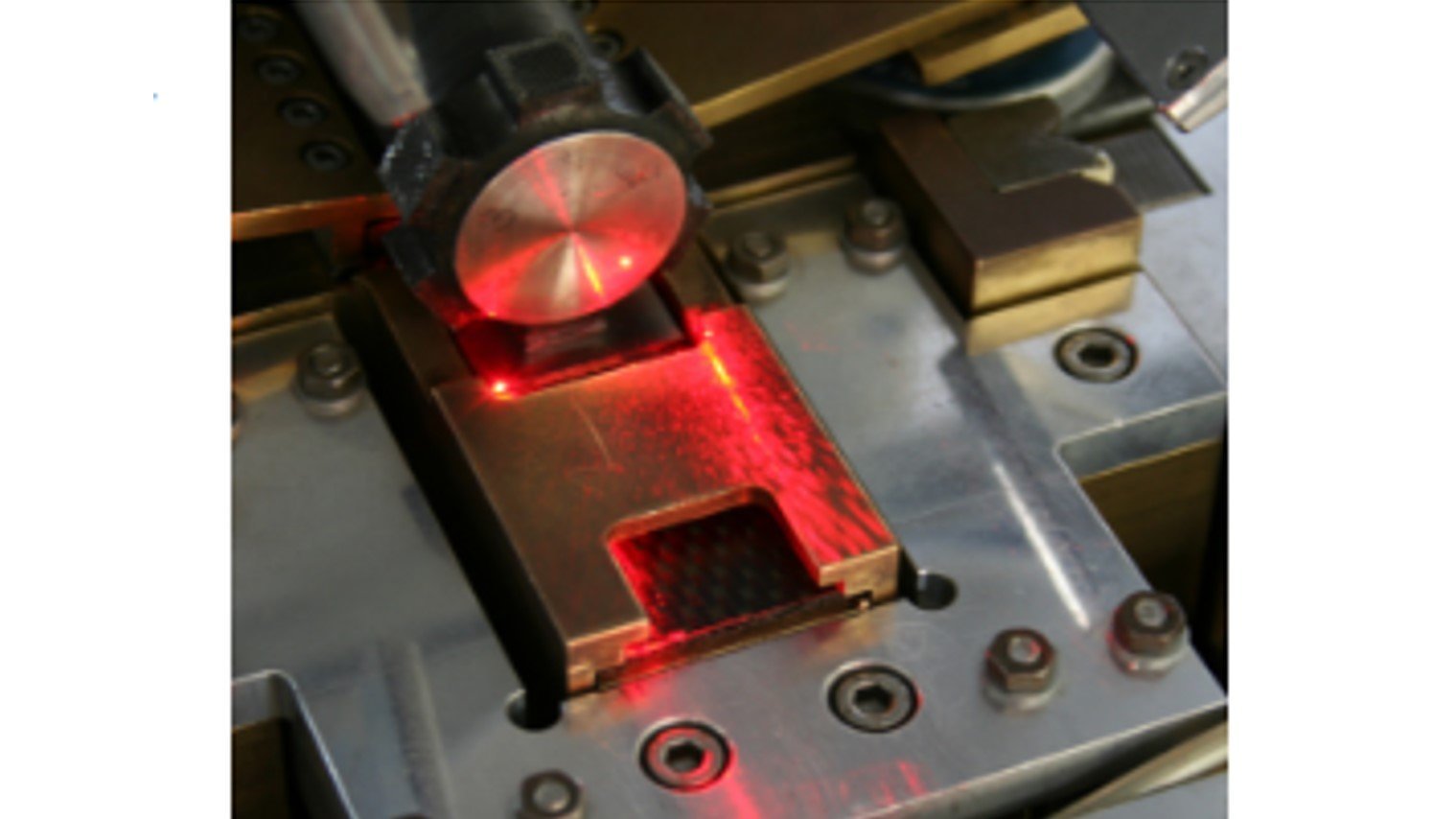

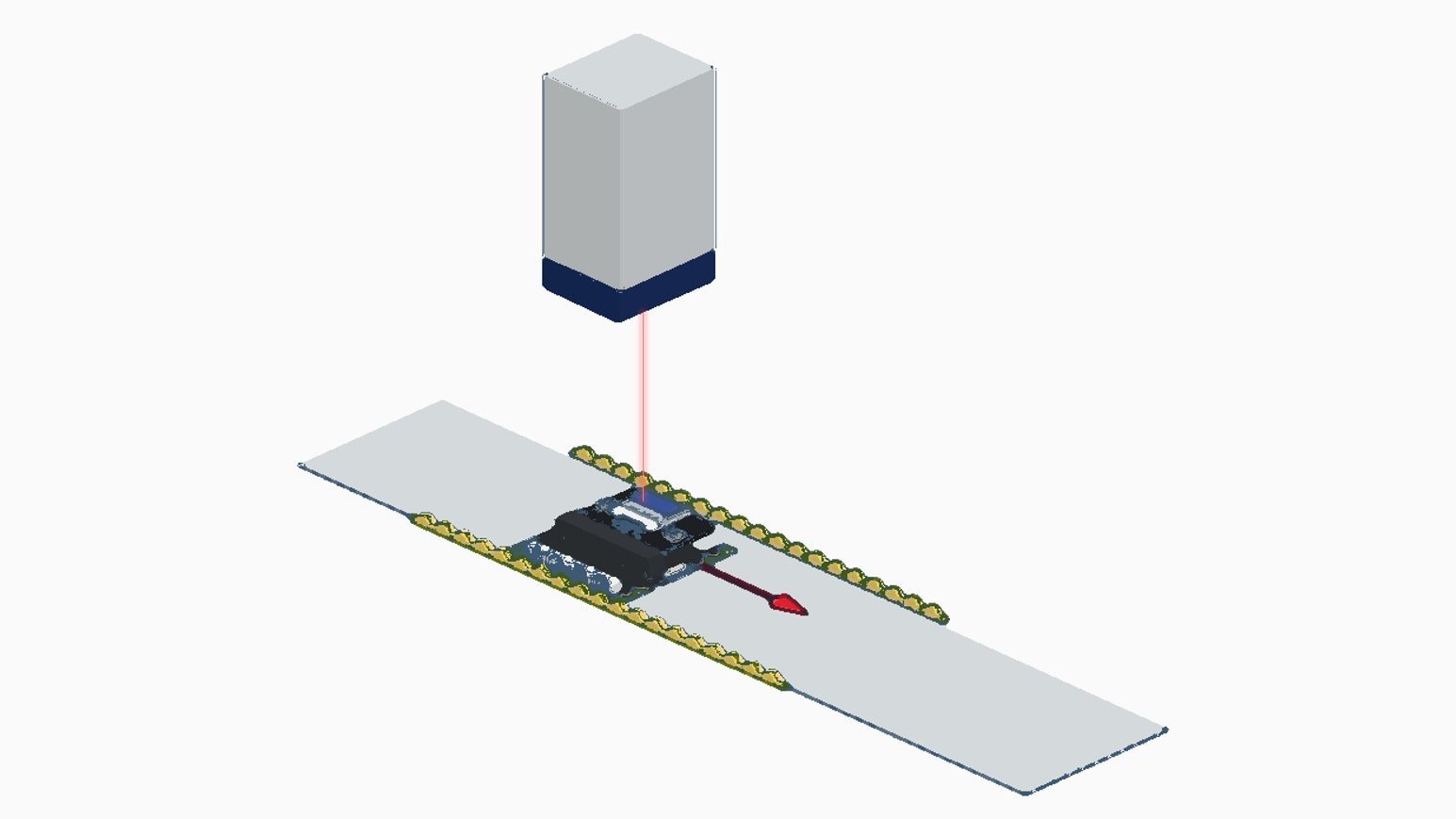

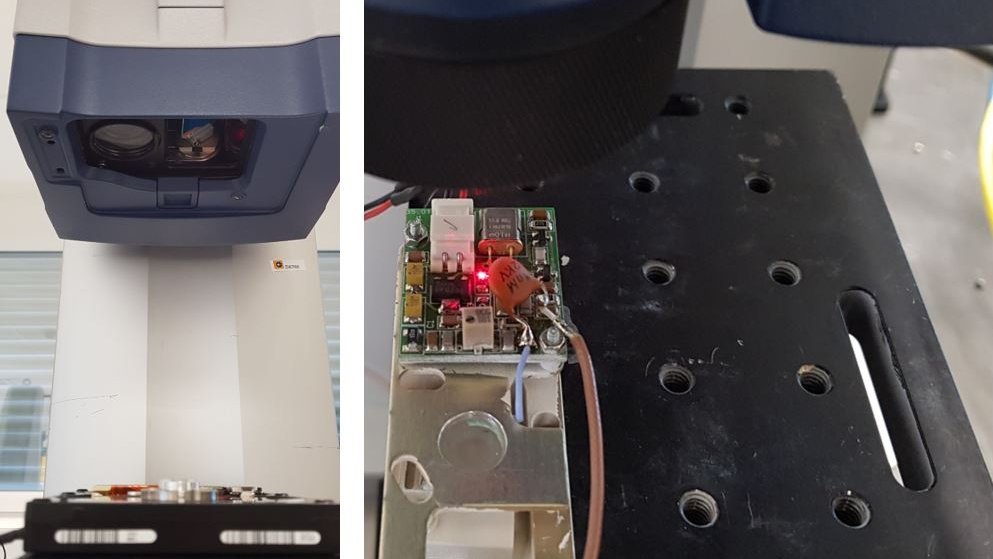

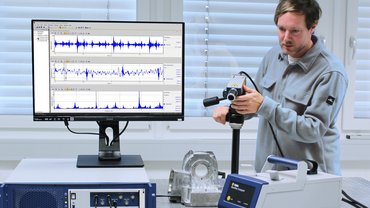

Optical measurement technology helps ensure the quality of acoustics and vibration characteristics both in development and on the production line. Laser vibration measurement technology measures amplitudes independently of frequency, quickly and reliably. Scanning vibrometry, in particular, allows area-based and non-contact amplitude measurement and is commonly used in research and product development for FE model validation, prototype testing or design optimization. However, it can also be used to derive suitable measurement points for a subsequent targeted 100% inspection in production in order to reliably detect rejects in production. Scanning vibrometry is also an efficient production measurement technique when multiple measurement points or the full-field amplitude distribution need to be checked.

Measuring vibration amplitudes on a large frequency bandwidth, also as a service?

Optical metrology for measuring amplitude & frequency

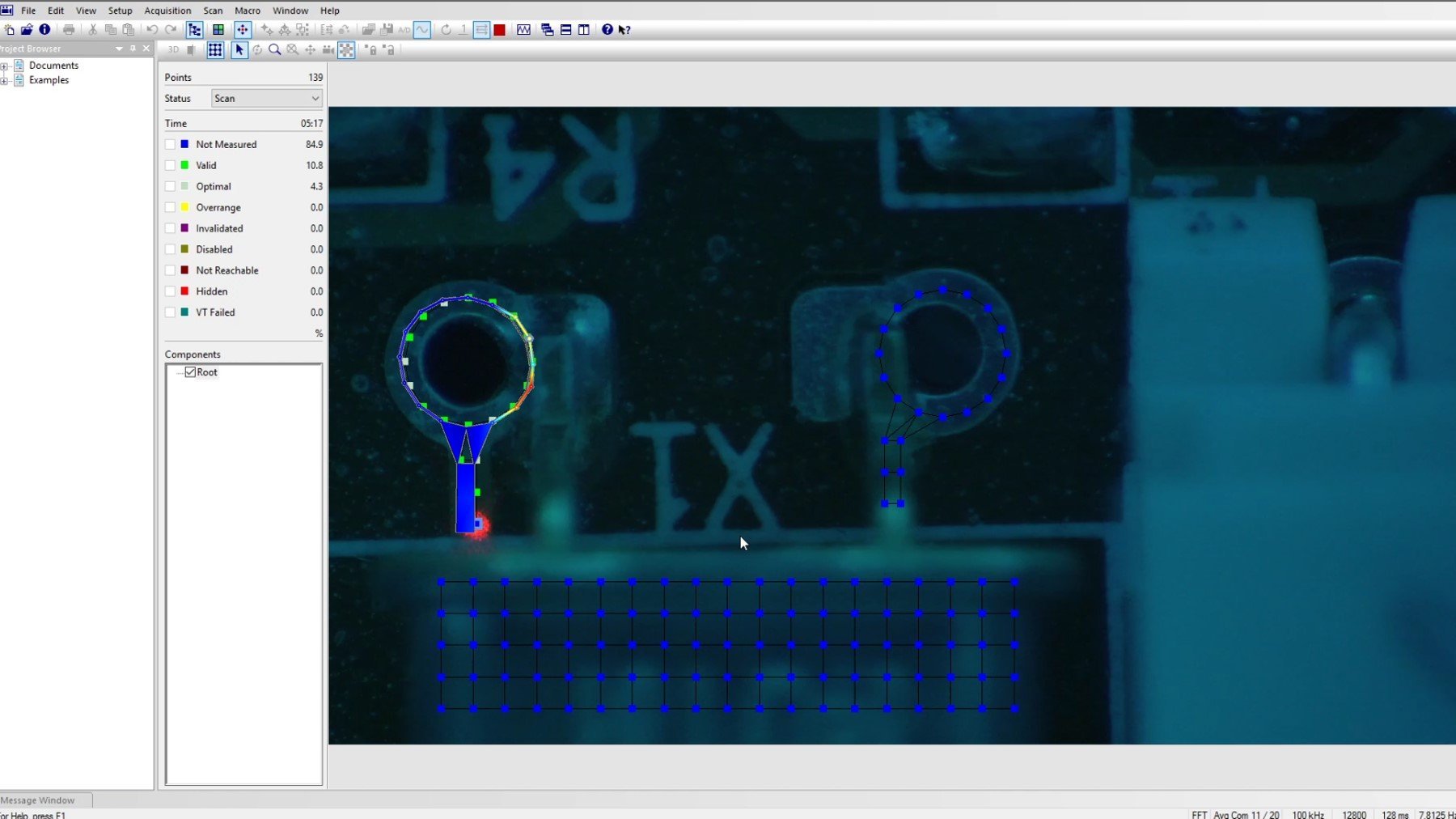

Amplitude correction in scanning vibrometry

Operational deflection shape (ODS) measurements with PSV Polytec Scanning Vibrometers require a stationary excitation. If this is not the case, a direct observation of the measured amplitude will not provide a meaningful result. This application note provides a path to a corrected amplitude using the integrated tools of the PSV software. Login to read the full guide on how to compensate non-static excitation using the transfer function.