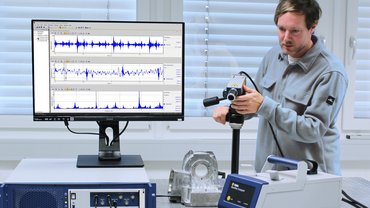

Production testing and quality control of white goods

In the consumer and capital goods industries, both product optimization and process optimization play a vital role when it comes to economic success. Experience has shown that spot checks performed on systems selected at random do not result in a reliable outcome. Only carrying out a complete check on the finished products guarantees a high quality standard. You should therefore opt to perform vibration tests with laser vibrometers from Polytec. Vibration analysis is ideal for distinguishing good products from faulty ones, which is why it is advisable to use vibrometers for quality control purposes. Laser vibrometry has established itself as the method of choice for non-contact testing. With the help of the laser vibrometer, the system reliably detects potential defects such as faulty or loose components or machine imbalance and provides information on the specific cause of the fault.

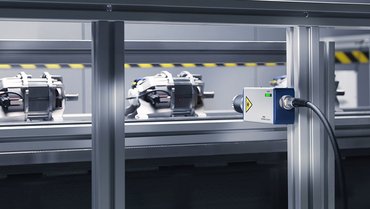

Noise and vibration inspection on motors for household appliances

Electrically driven household appliances or their components which generate unwanted vibrations and noise are reliably detected in production by laser vibrometers and removed from the process. Examples include washing machines, vacuum cleaners and electric toothbrushes.