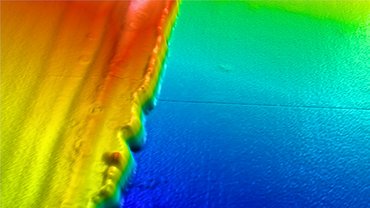

Check and optimize friction

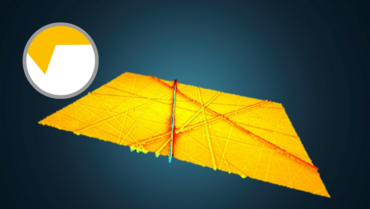

When it comes to tribology – that is, the science of friction, lubrication and wear – surface properties play a very important role. These parameters can be controlled as desired by simply changing the surface. However corresponding measuring instruments are needed for this, since only powerful surface measurement methods enable development of suitable components. The perfect conditions for checking wear and optimizing lubrication are only created by refining surfaces.

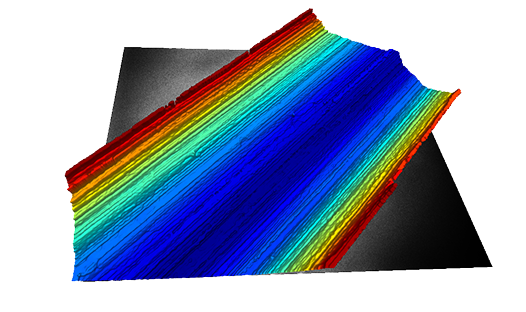

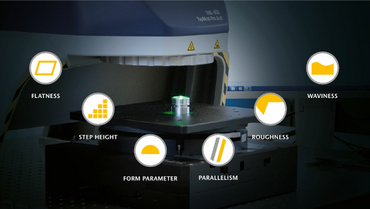

The surface measurement systems from Polytec allow you to measure a variety of surfaces, whether they’re polished, rough or textured. Both the form and the function of the test object are maintained thanks to the contactless measuring method. Polytec products provide you with excellent resolution, right down to the nanometer range. You can choose to use integrated filters for different reflections. The special software is easy to use and can be adapted to your working conditions without a single problem.

How to assure proper lubrication and defined roughnes values?

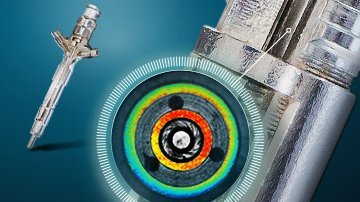

Check for proper lubrication

Continuous and defined lubrication as well as steady distribution of the lubricant in air bearings can be determined precisely and without contact. Use the large-area measuring whitelight interferometers of the TopMap series as a precision tool for quality control and optimization.