Characterizing flexible electronics in 3D

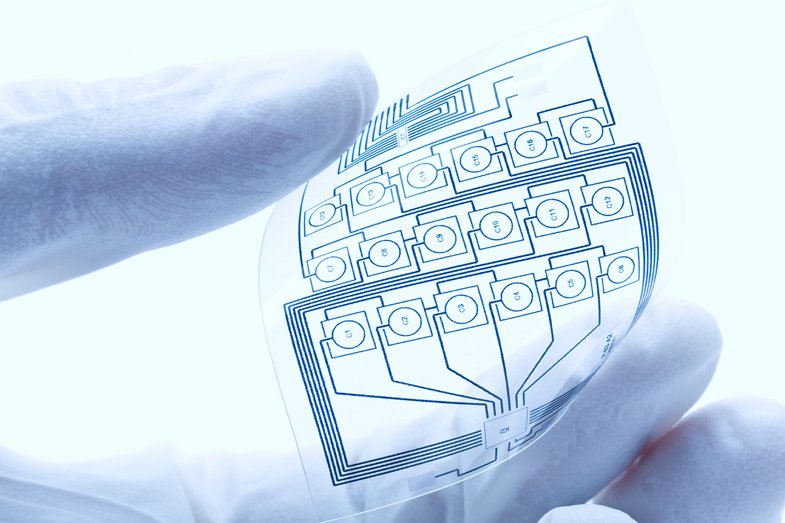

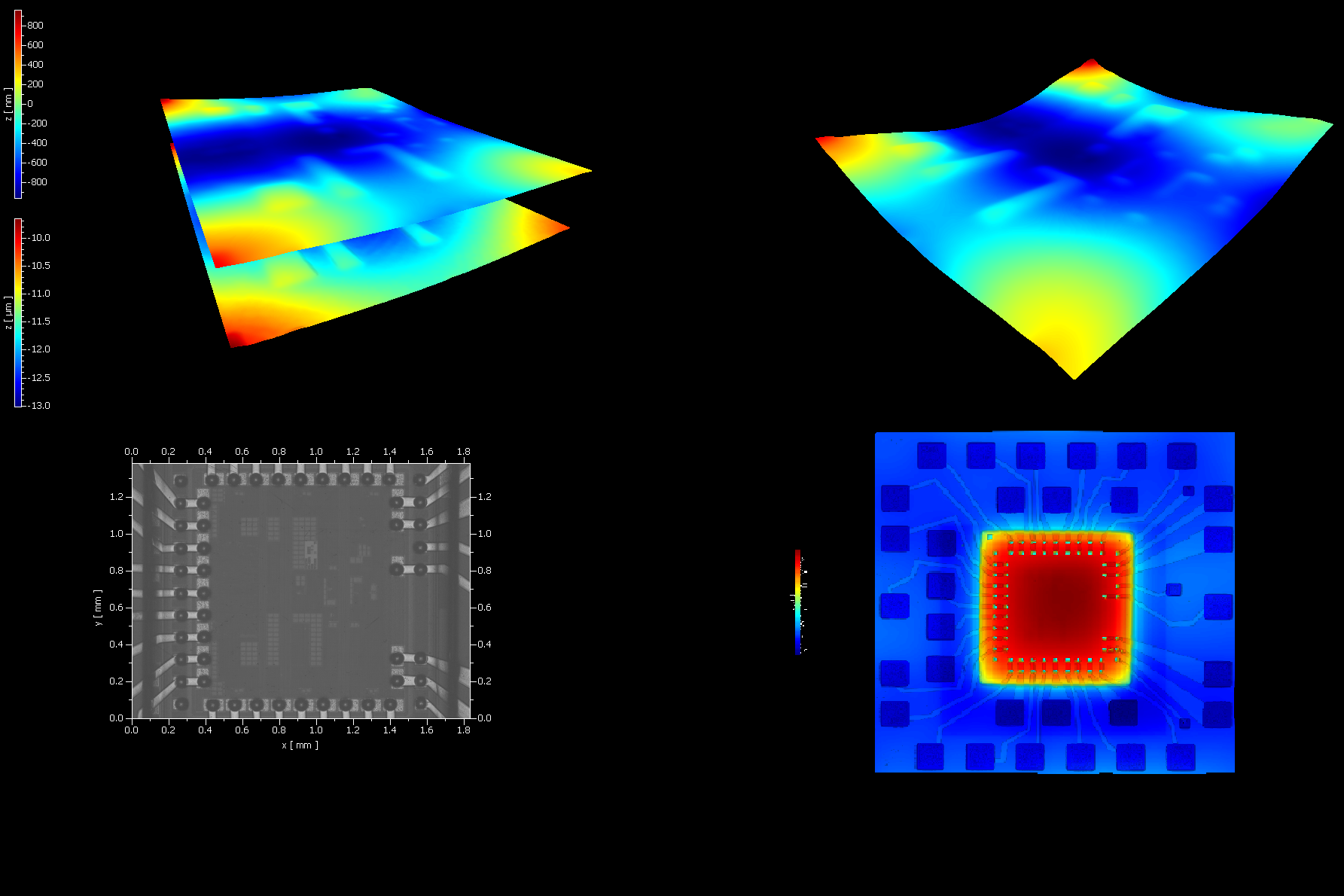

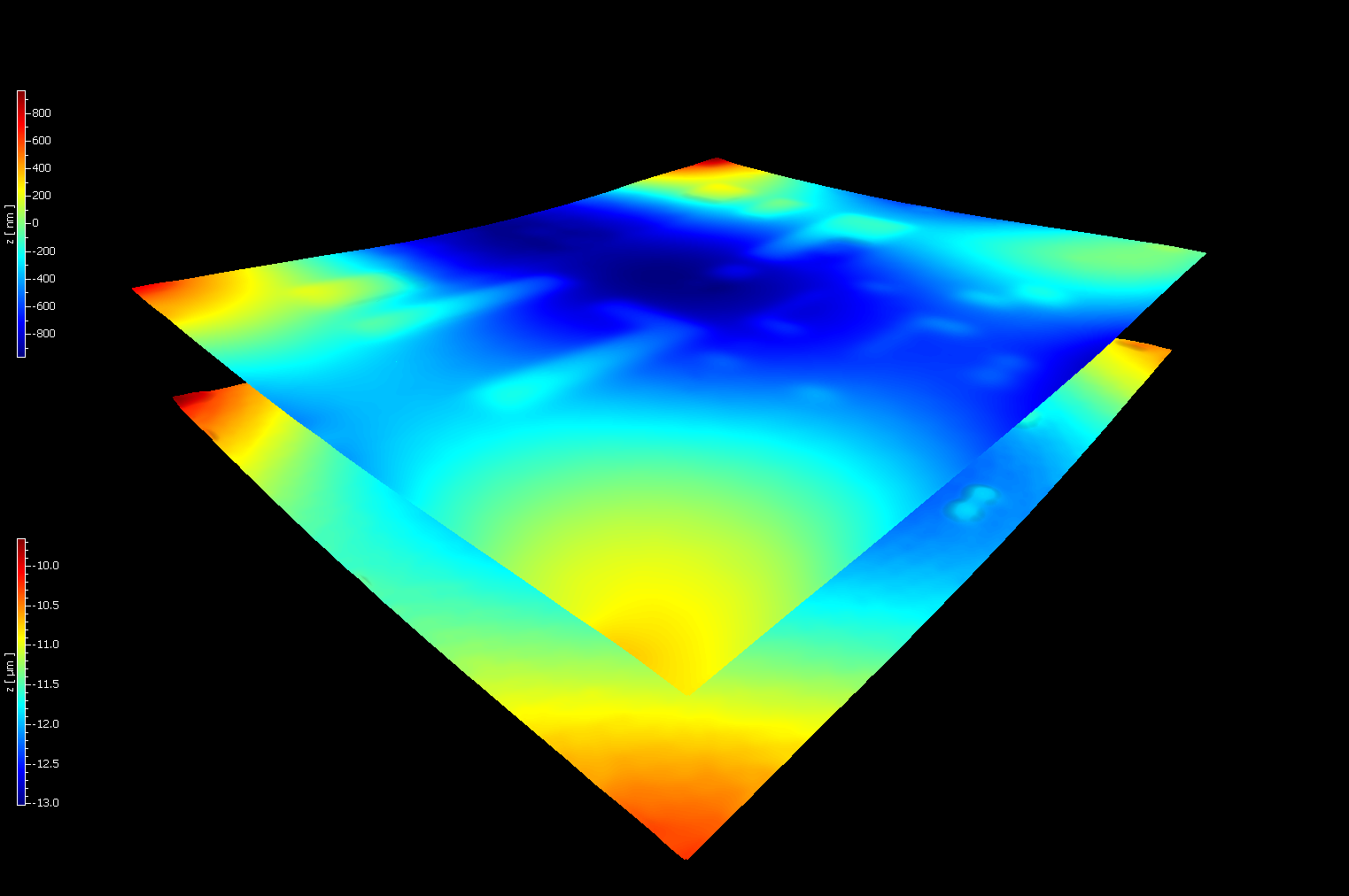

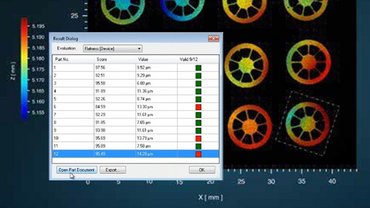

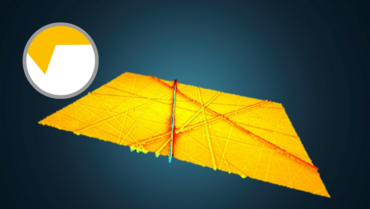

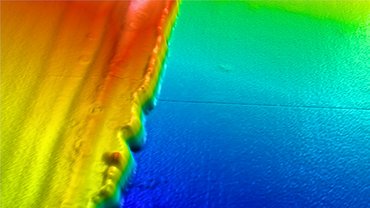

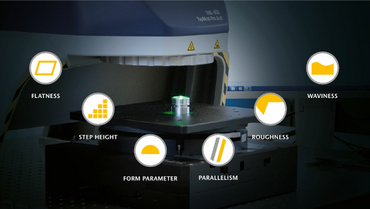

Flexible electronics open up a realm of new applications in the fields of wearables, thin film solar cells, RFIDs and displays used in automotive dashboards or medical applications. For all these use cases, the product reliability is a key quality indicator. Also there is an increasing demand in components to be harmonized for signal processing, communication and energy generation. For such applications, white-light interferometry allows scanning the entire surface of hybrid flexible electronics in a single shot. The optical and non-destructive measurement method characterizes printed electronics on behalf of form parameters, roughness and structural details and help secure the electronics quality and functionality.