Table-top optical surface profiler

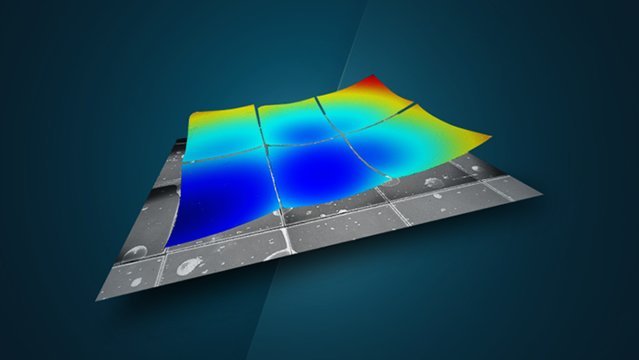

TopMap Micro.View® is an easy to use and compact optical profiler. Combine exceptional performance and affordability with this powerful metrology solution. With an extended 100 mm Z measurement range and the CST Continuous Scanning Technology, Micro.View® measures complex topographies at nm resolution. This convenient table-top setup features integrated electronics, with the smart focus finder simplifying and speeding up the measurement procedure.

Highlights

- Measure surface finish in a compact setup

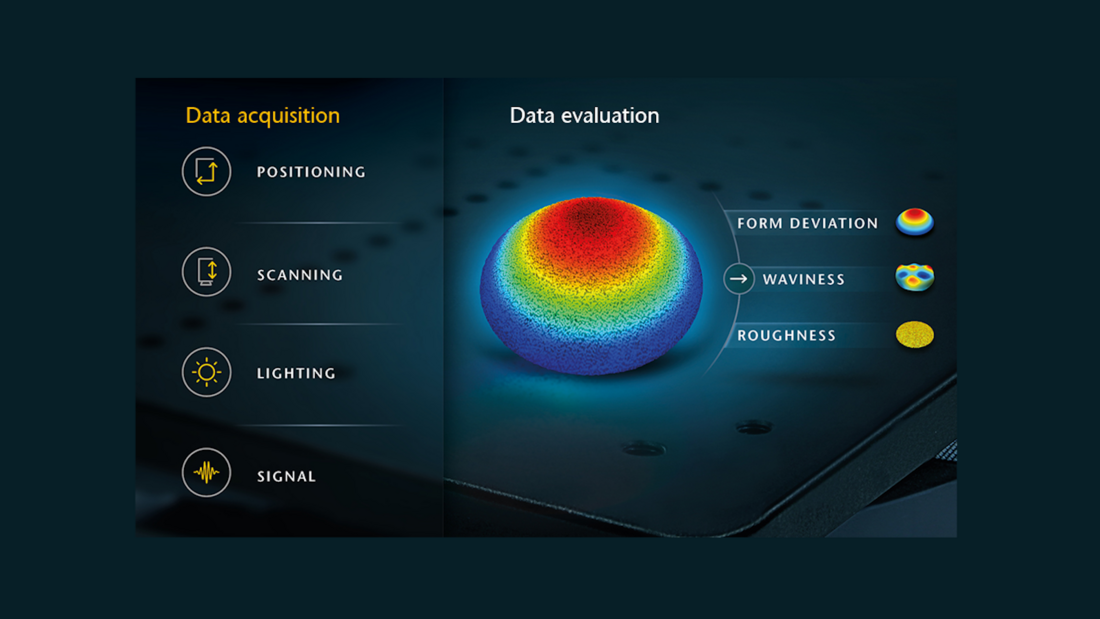

- Non-contact measurement of 3D topography, roughness and texture

- 100 mm z measurement range with CST Continuous Scanning Technology

- Excellent lateral resolution

- Choose from application-specific objectives

Microscope system for surface profiling

White-light brings out the finest details of your precision engineered surfaces. Microscope objectives allow for characterizing the surface finish and quantifcation of how rough or smooth your workpiece surfaces is. Benefit from motorized surface measurements and automated positioning. The Focus Finder assists you automatically, so you can focus on your surface quality.

Precision measurement is about experience, about expertise and about experts and technology we trust in. Take a look behind the scenes, learn more about the development and about the people behind TopMap and meet the PolyXperts. Come join our journey!