Measuring acoustics, resonance or vibration for reliable production testing

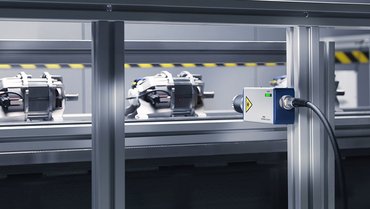

In industrial manufacturing of consumer and capital goods, both product and process optimization play the key role for sustainable economic success. Quality assurance in production therefore relies on fast, automated and robust testing and measurement instrumentation. Acoustic quality control as the detailed detection of structure borne noise is quite a versatile, non-destructive testing method. Acoustic inspections are designed to ensure the quality and reliability of products and thus the entire manufacturing process. Acoustic quality testing equipment supplies information about vibration behavior in real-time and helps keep detect deviations and reduce rejects early in the production process, way before a critical failure. Polytec industrial laser vibration sensors inform in real-time about the condition of test objects.

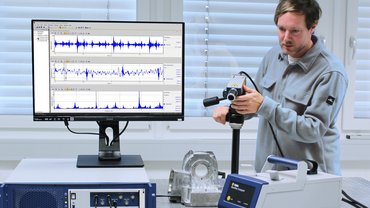

Acoustic quality control with laser precision

Polytec offers complete solutions: sensors, software and hardware modules. The laser vibrometers are robust and reliable sensors for quality control of complete parts in final production testing or in end-of-line testing. Major benefits using laser sensors are the non-contact and non-destructive nature, the fast setup and simple integration into industrial manufacturing processes and the flexibility to cope with varying samples in manufacturing lines using auto-focus. Polytec vibration sensors are compatible and easy to integrate into existing test stations as comprehensive, powerful production testing solutions. Use also the Polytec diagnosis software QuickCheck for automatically measuring and evaluating the measurement data for reliable pass-fail decisions and classification of parts.