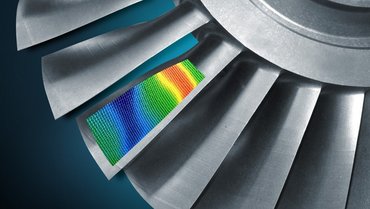

Aerospace research accelerated by laser vibration testing

Test engineers need high-quality tools and simulation engineers need precise measurement data. Such data is necessary in order to carry out critical tests to meet the demands of uncompromising safety, reduced fuel consumption through the use of composite materials and drive concepts, as well as new materials and CAE-supported development processes. That’s why you should reach for Polytec tools when carrying out important applications in the field of dynamic measuring technology. Both turbine durability validation and the development of new NDT methods or a classic modal test will likewise benefit from vibration sensors that supply reliable results in a non-intrusive way. These can even be achieved in a vacuum, over long distances and under all temperature conditions. You can determine transfer functions, deflection shapes and strain distribution quickly and without any need for the time-consuming process of instrumentation.