Superior roll gap control by laser precision

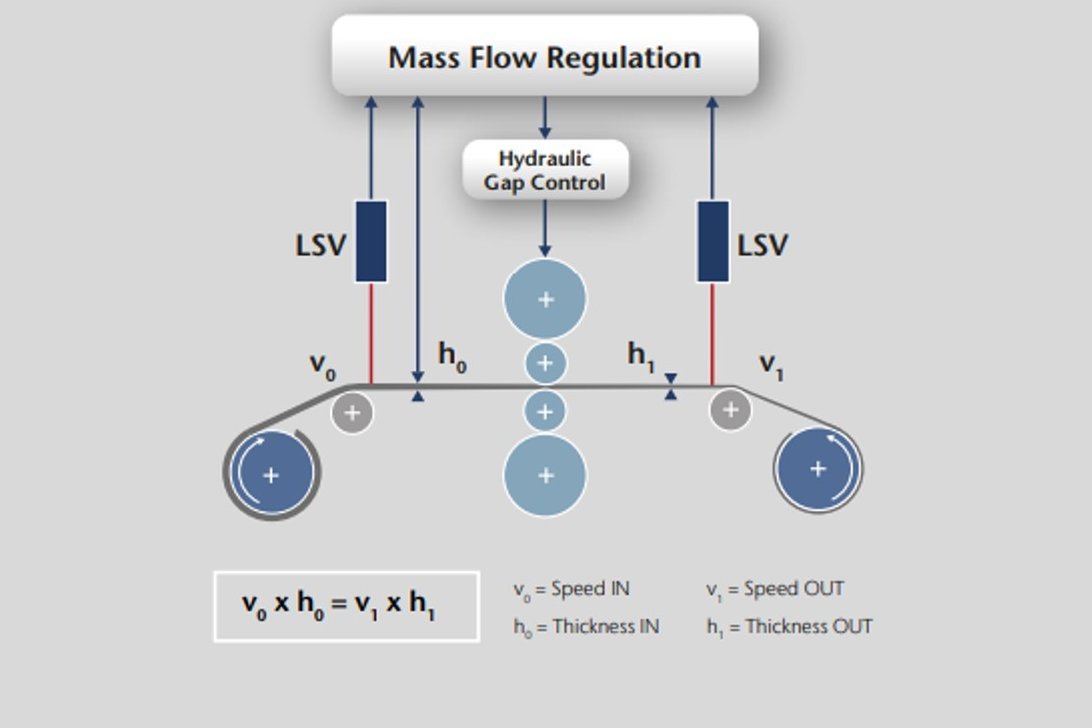

In steel rolling mills, the thickness of the finished coil is an essential quality parameter: Controlling the roll gap plays the crucial role in achieving the specified thickness tolerance throughout the length of the coil. Non-contact, optical sensors for precise material speed measurement at the entrance and exit of the roll stand enable fine adjustment of the roll gap for dynamic process optimization.

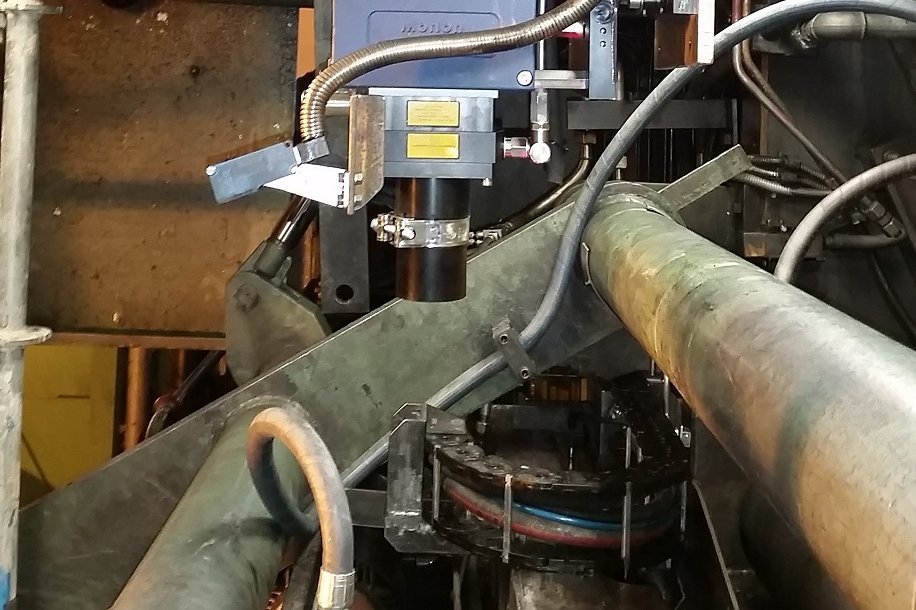

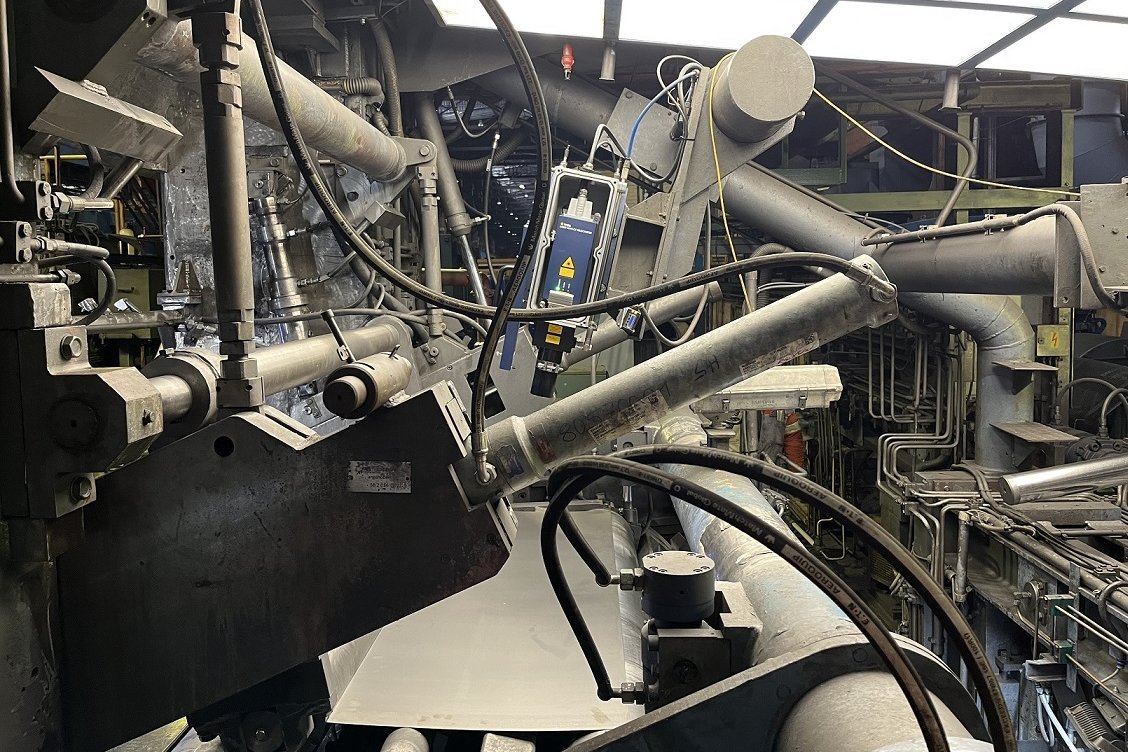

Laser Doppler based sensors like Polytec’s ProSpeed® LSV (Laser Surface Velocimeter) help to improve thickness control and product quality by allowing for enhanced roll gap control, especially during periods of acceleration and deceleration.

Roll gap measurement & thickness opimization in Rolling Mills?

Measuring roll gap width & process speed in rolling mills with laser precision?

Controlling the roll gap width with laser sensors

Roll gap control benefits significantly from the use of Polytec's LSV Laser Surface Velocimeters. LSVs measure the strip speed highly accurately and reliably on many surfaces from glossy to matt according to the laser Doppler velocimetry. Even on dirty or oily surfaces, the LSV provides a stable measurement signal for process control. In contrast to alternative measuring methods, the LSV does not experience any slippage or wear, which means that the roll gap can be precisely adjusted without being affected by the material.

Encoders for Cold Rolling, Hot Rolling, Tandem or Reversing Mills

Controlling the roll gap via skin pass and stretching degree

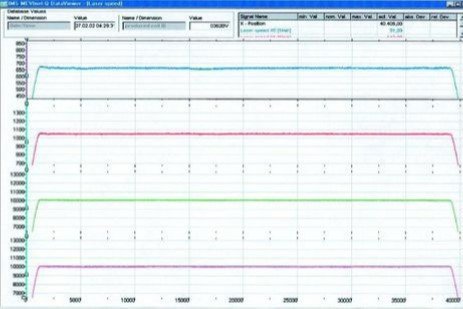

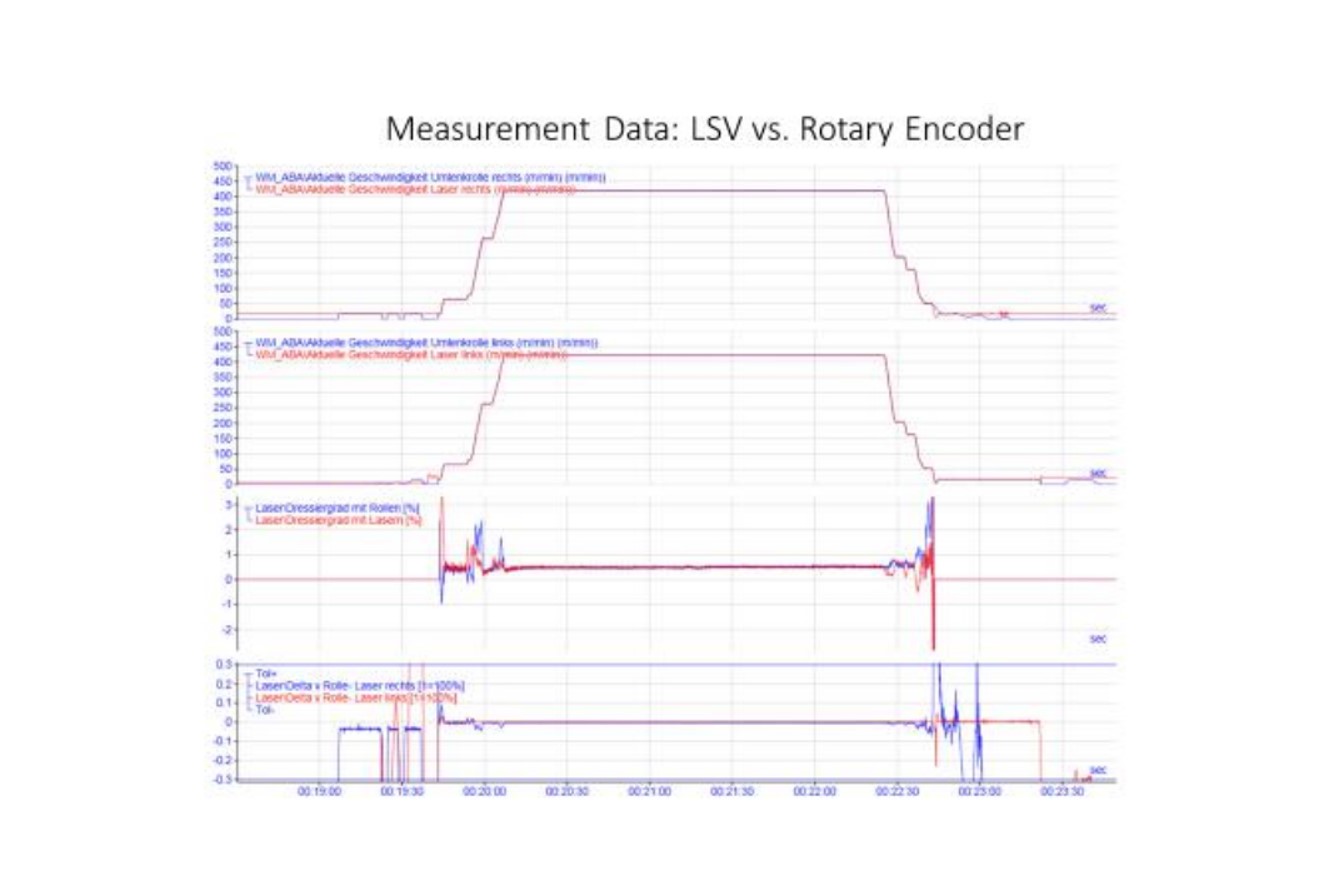

The control of the roll gap during cold rolling is decisevely influenced by the precise measurement and control of the strip speed at the infeed and outfeed of the roll stand. Mechanical contact based tachometers are traditinoally used for this purpose. However, contact methods of measureing strip speed are susceptible to slip and wear, resulting in measurement errors – especially evident during acceleration and deceleration.

These precise measurements become the basis for fine-tuned control of the roll gap, showing significant influence on the mass flow control. By using this optical measuremen technology, major stainless steel manufacturers worldwide had proven to significantly improve the accuracy of their roll gap control, achieving a reduced measurement uncertainty of the skin pass degree down to ± 0.02 %!