Determining material parameters in a non-destructive way

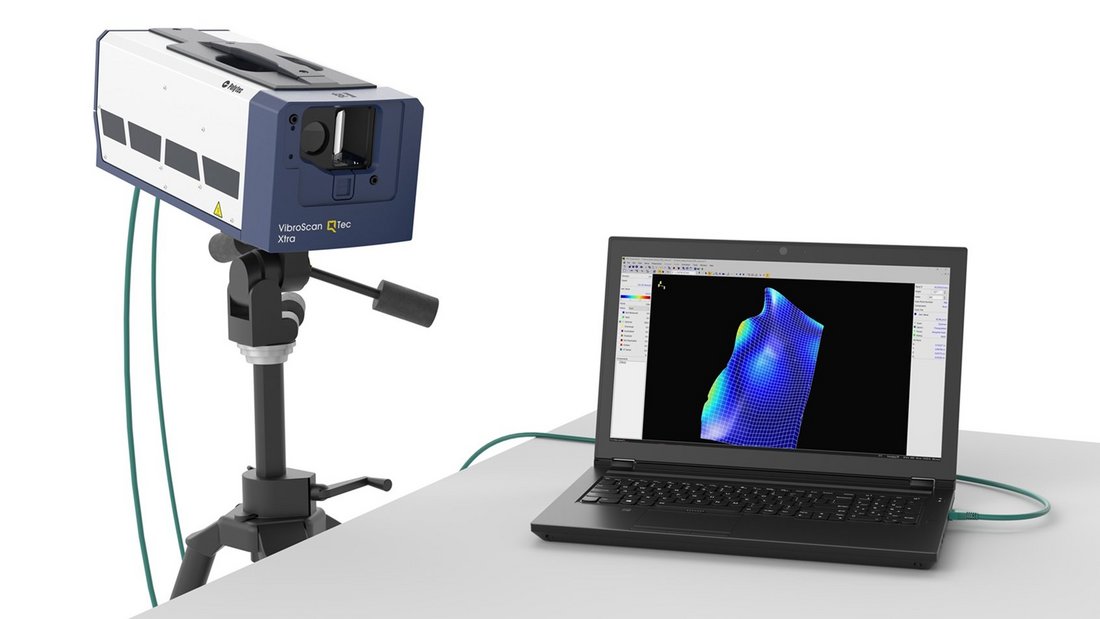

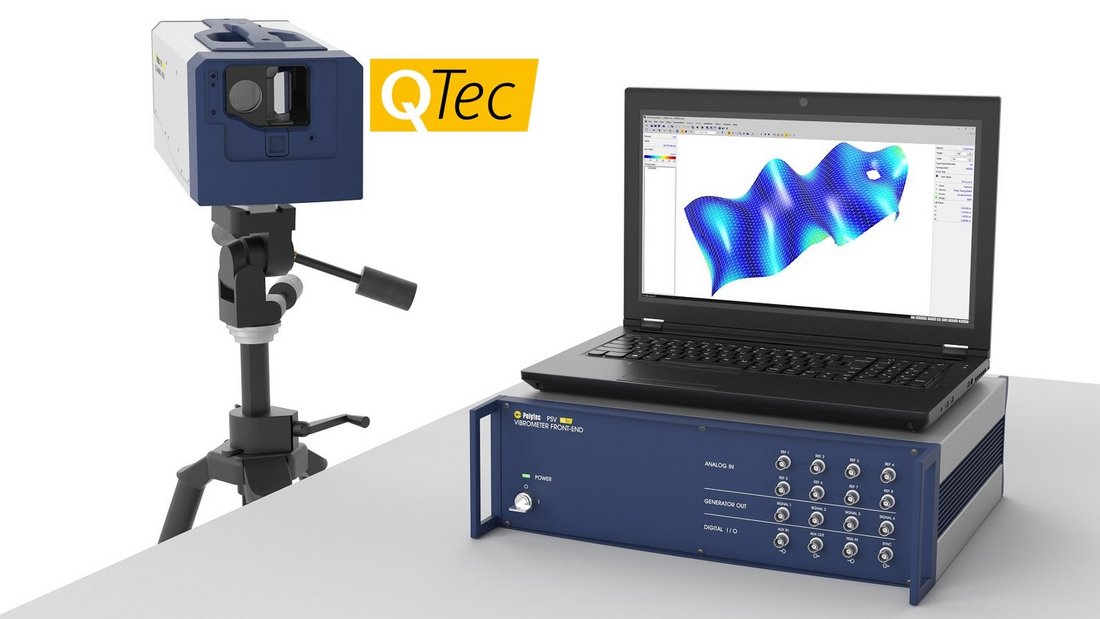

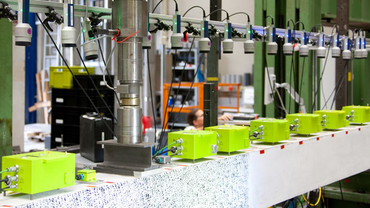

Material properties are determined with zero contact using laser vibrometers. Conclusions can be drawn as to a material sample’s strength by determining the resonance frequency during broadband excitation. This method is used to ensure quality when manufacturing different building materials, since it is completely non-destructive. Often expensive test objects can be saved, and it can also be easily automated.

Polytec Magazine

Of colors and shapes

Vibration analysis helps to protect art

Construction material requiring non-invasive testing

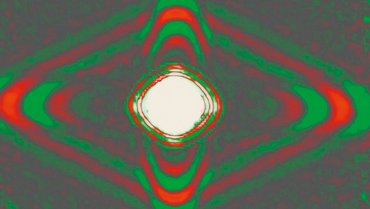

Knowledge of the temporal and local changes to the material properties of cement-bonded systems is vitally important for both materials research and for planning and implementing construction projects. The material properties can be described using ultrasound parameters. Cement-bonded building materials have a high ultrasonic wave absorption capacity straight after mixing, as well as a low sound velocity. Depending on how structure development progresses, the sound velocities and signal amplitudes then increase continuously. The surface’s ultrasound-induced deflection is recorded with zero contact using laser vibrometers. Calculating Young’s modulus and Poisson’s ratio – the elastic variables – also allows for a more extensive assessment of the materials inspected.