Optimizing tire acoustics by model validation

Designing the optimal tire is always a trade-off between mileage, longitudinal and lateral dynamics, wear as well as acoustics. Here, laser vibrometers help building the bridge between FE simulation and real test, as the model validation on rolling tires are the fundament for optimizing the tire as a system.

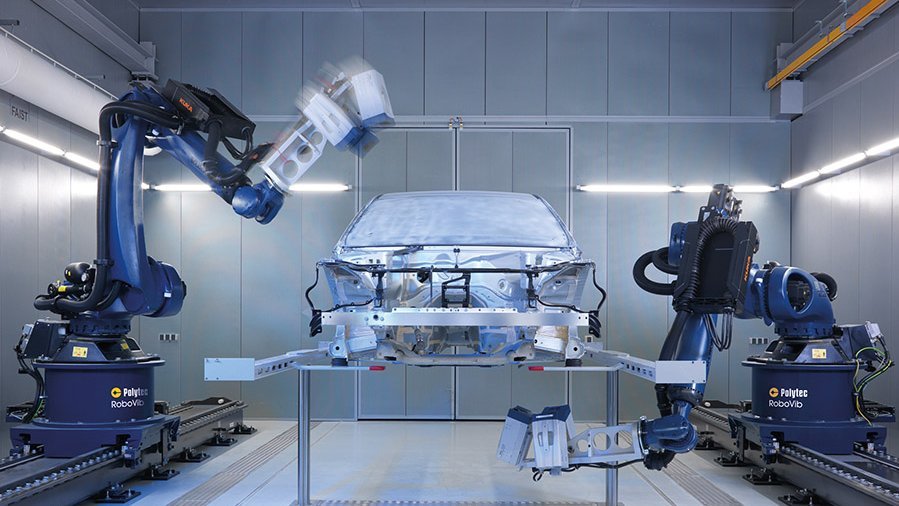

The most important issues about tire acoustics is the influence of the rolling tire on the interior acoustics of the passenger car in order to comply with the increasing official regulations regarding noise emission all over the world. Full-field vibration analysis reveals not only the operational deflection shapes of the tire side walls including chassis parts, but also help determining the transfer paths. Laser Doppler Vibrometry provides the unique properties to measure right on the rolling tire on the acoustic test bench. Introducing Polytec’s Xtra laser technology, the optical vibration sensor gathers enough backscattered light even from dark rubber to scan the entire side walls plus the original source of noise: the tire tread. The PSV-3D Xtra Scanning Vibrometer captures the surface vibrations of the tire in 3D without contact, offering detailed information about structure-born noise from the complete tire tread. This allows engineers to visualize and describe the vibrational behavior quantitatively and qualitatively.

Why measure tire acoustics with Xtra laser technology?

This advanced method of laser vibration measurement together with a powerful evaluation electronics enables capturing also high vibration velocities which even works at an angle on the tire tread. Before, the angle of incidence of the laser beam has been a challenging condition for such measurements. The Xtra laser technology successfully overcomes this limitation making the Polytec Laser-Doppler vibrometry the ideal tool for analyzing and optimizing tire acoustics.